Whether you are a seasoned mechanic or just purchased your first shock dynamometer, knowing how to read shock dyno graphs is a crucial skill to master.

In this article, we will cover all the graphs LABA7 software generates and cover some background for starting suspension professionals. We will also share tips and tricks for reading shock dyno graphs as well as real examples of graphs of shocks we test in our R&D department.

Table of contents:

- Key terminology in reading shock dyno graphs

- What is a shock dyno?

- LABA7 shock dyno software

- Shock dyno graphs explained

- Why Shock Dyno Graphs Matter?

- How to Use Shock Dyno Graphs for Better Performance?

- Conclusion

Key terminology in how to read shock dyno graphs

In this section, we will cover some of the basic terminology used when working with shock dynos. If you are an experienced user, feel free to skip to another section.

Shock

What it is, what it does, what shock damping is, how does damping work, and other questions we covered in detail in our exhaustive guide to shock absorbers?

But in short, a shock (shock absorber, fork, or damper) is part of a car, bicycle, or motorcycle suspension. Whatever the name, its purpose is to reduce shocks and vibrations caused by uneven roads thus improving the handling and comfort of a vehicle.

Dynamometer

Also called dyno for short. By definition, dyno is an instrument that measures the power output of a motor. Dynamometers are used to test various parts or components and help diagnose issues or assure quality.

Shock dyno

A shock dyno is an instrument specially designed to test and diagnose shock absorbers. We will answer the question “What is a shock dyno” in full in the next section of this article. Or you can visit the LABA7 shock dyno page to get acquainted with our range of dynos.

Dyno graph

A shock dyno graph is the most convenient and easy-to-understand way to represent the results of a shock absorber test.

The LABA7 shock dyno records information at the speed of 64,000 times per second. Providing the results in any other format would be impossible for humans to understand, not to mention identify if there are any issues.

Our software accumulates all data entries and represents them in graphs where the performance of the shock absorber can be easily evaluated.

Sometimes, people call them dyno sheets. Especially, if they are printed out.

Scotch-Yoke mechanism

It translates the rotational motion of the motor into the vertical linear motion of the shock absorber. The Scotch-Yoke mechanism can be considered a sign of quality as it greatly improves the accuracy of the data the dynamometer collects.

Oscillation

It means moving back and forth in a regular rhythm. For example, shock absorbers act to dampen the oscillation of the spring.

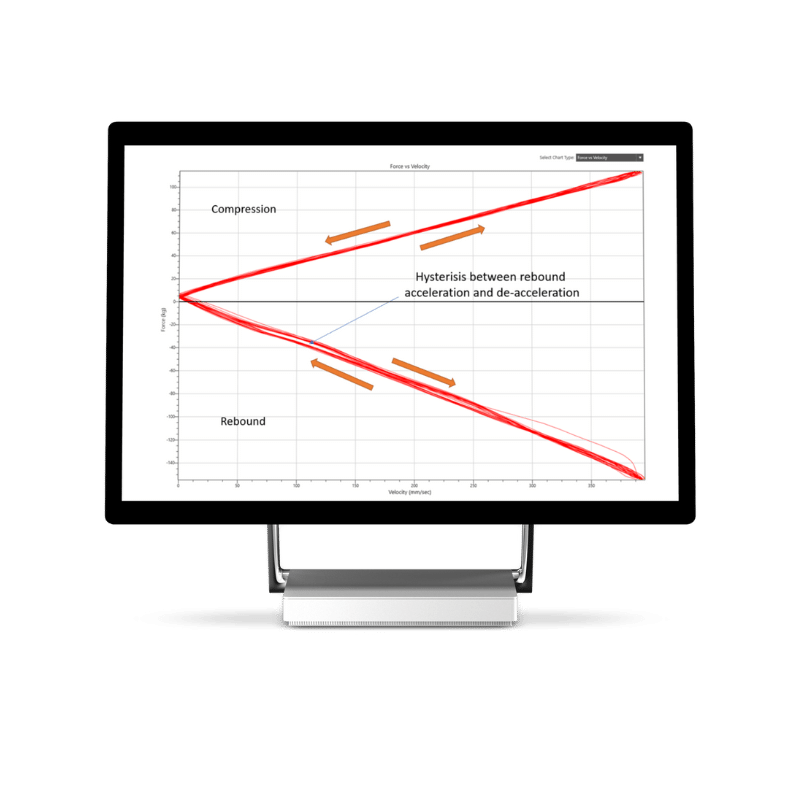

Hysteresis

Hysteresis in shock dyno graphs refers to the difference between the damping force during compression (or rebound) and the damping force during the return motion at the same velocity. It indicates energy loss within the shock absorber system, usually due to friction, fluid dynamics, or mechanical inefficiencies.

In the graphs, hysteresis is shown by the separation of the two lines in the graph. Below you will find shock dyno graphs that illustrate hysteresis.

What is a shock dyno?

A shock absorber dynamometer is a vital tool for evaluating and improving suspension performance.

It measures the rebound and compression forces of a damper and helps to identify if it has any issues and correct them. This makes the shock dyno a must-have tool for building, rebuilding, or tuning suspension.

For drivers and riders who seek top performance in any competitive event, shock dyno is basically irreplaceable. It allows them to fine-tune their suspension and, as a result, achieve better times.

With correct adapters LABA7 shock dynos can test any shock absorber on Earth. Whether they are used in bicycles, motorcycles, cars, trucks, buggies, or any sports vehicle.

Visit this page if you are looking for a shock dyno for sale.

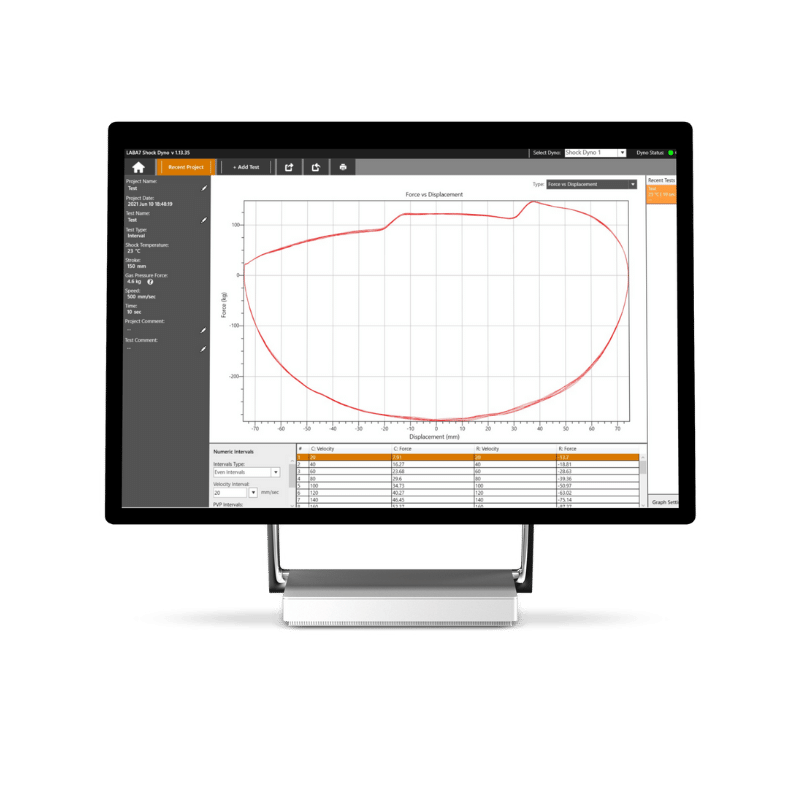

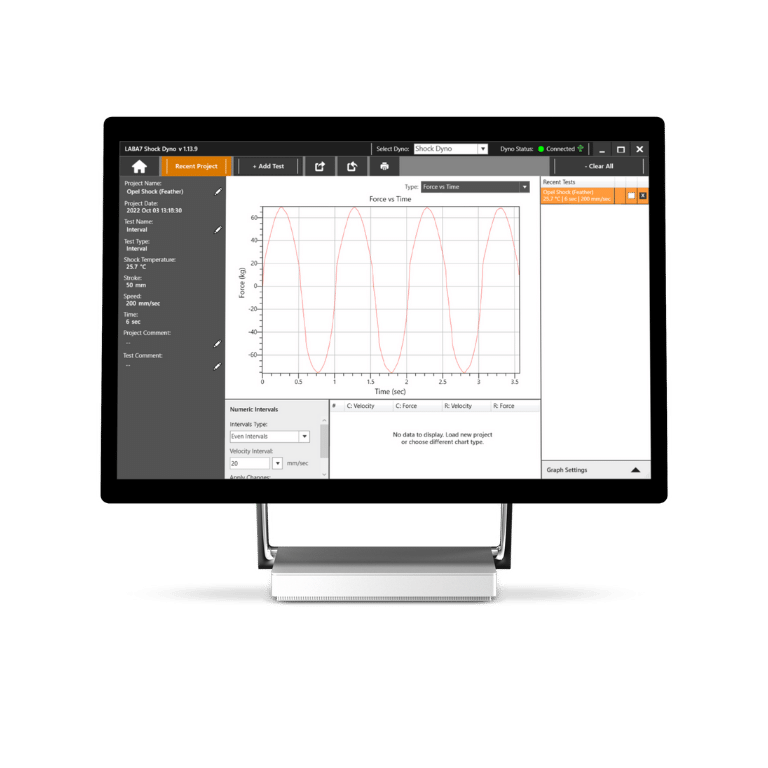

LABA7 shock dyno software

LABA7 shock dyno software is developed with the user in mind. The software is intuitive and easy to use. At the same time, it has all the features and delivers the most accurate data in the market. And it runs on Windows OS!

Here is how the LABA7 shock dyno hardware and software work:

During the test, the Scotch-Yoke mechanism creates shock-absorber oscillation. The load cell of the shock dyno captures the damper’s rebound and compression force data, while a high-precision displacement sensor monitors the travel of the shock absorber.

All data is then collected by our in-house developed data logger. Tens of thousands of data points every second are processed (no phase shift) and sent to the software on your computer.

It is important to stress that data is sent in real-time over WiFi. It means that you can track and analyze the performance of the shock as it happens.

When LABA7 suspension dyno software receives the data it generates dyno graphs on your screen. The operator of the dyno can detect and fix malfunctions or tune the suspension to perfection.

All details on how to read shock dyno graphs you can find in the section shock dyno graphs explained.

Features

Zero tare

Before we start explaining how to read shock dyno graphs, it is very important to note that the shock dyno must reset the sensor at the right spot. This avoids dyno graphs being offset and inaccurate.

LABA7 shock dyno software does this automatically, so our graphs are always spot on.

Gas pressure elimination / Spring elimination

Another smart feature we have implemented is spring elimination. It helps when you are measuring air spring forks or motocross bike forks.

Moreover, you can measure theoretical gas pressure in the shock and eliminate it from the graphs.

Print reports

With LABA7 software you are able to print your graphs (even the comparison of graphs) by a press of a few mouse buttons.

You can upload your company logo and contact details as well!

Shock dyno graphs explained

Below you will find tips on how to read shock dyno graphs. All shock dyno graphs were generated by LABA7 shock dyno software during a single test. Not only that – we explain how it is measured, how to interpret the results and share our tips to achieve the most accurate results.

As these graphs are real examples of actual tests we concluded, what else can be better material to learn about dyno graphs?

Temperature Vs. Time

The LABA7 software offers a practical feature: a live temperature graph. Temperature measurements are taken by an infrared sensor with an accuracy of 0.5°C. Reading is done every 1 second on the graph.

This functionality proves particularly useful for evaluating how well your shock absorber handles temperature dissipation at different speeds.

Main applications of the temperature graph:

- Preparing the shock absorbers. Before conducting tests, it’s important to warm up the shock absorbers to their optimal working temperature. This ensures reliable and accurate results during the testing process.

- Monitoring temperature buildup. The graph allows you to observe how quickly the shock absorber’s temperature increases. This information helps assess its performance under various conditions and provides insights into heat accumulation.

- Identifying issues at high temperatures. By analyzing the temperature fluctuations on the graph, you can detect issues that may arise when the shock absorber reaches high temperatures. This helps you to identify the cause of the malfunction and fix it.

To ensure accurate measurements, remember these important notes:

- Avoid measuring on glossy surfaces, as they can affect the accuracy of the infrared sensor’s readings.

- Position the sensor to face the body of the shock absorber, enabling it to capture temperature variations accurately.

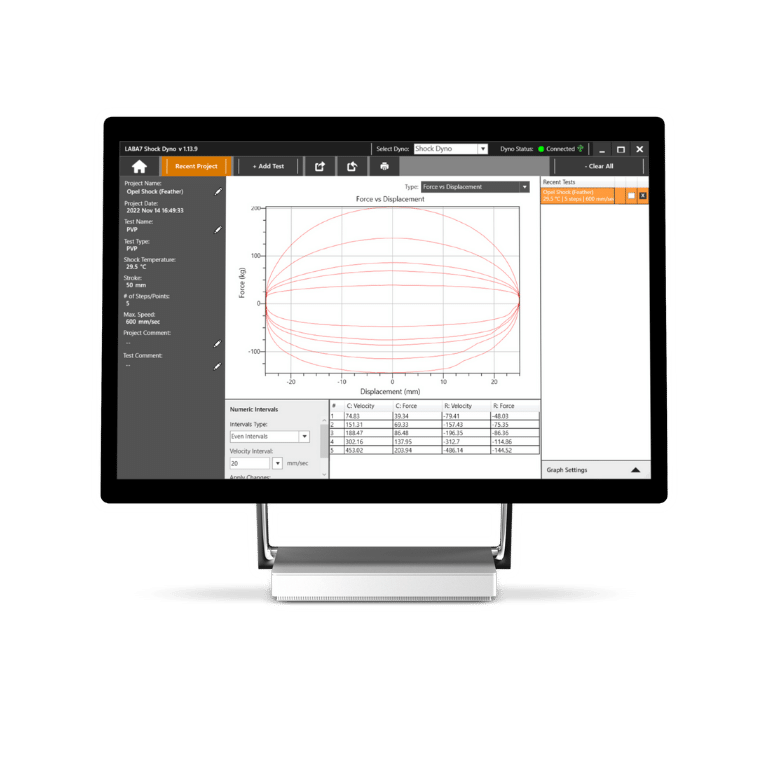

Force vs. Displacement

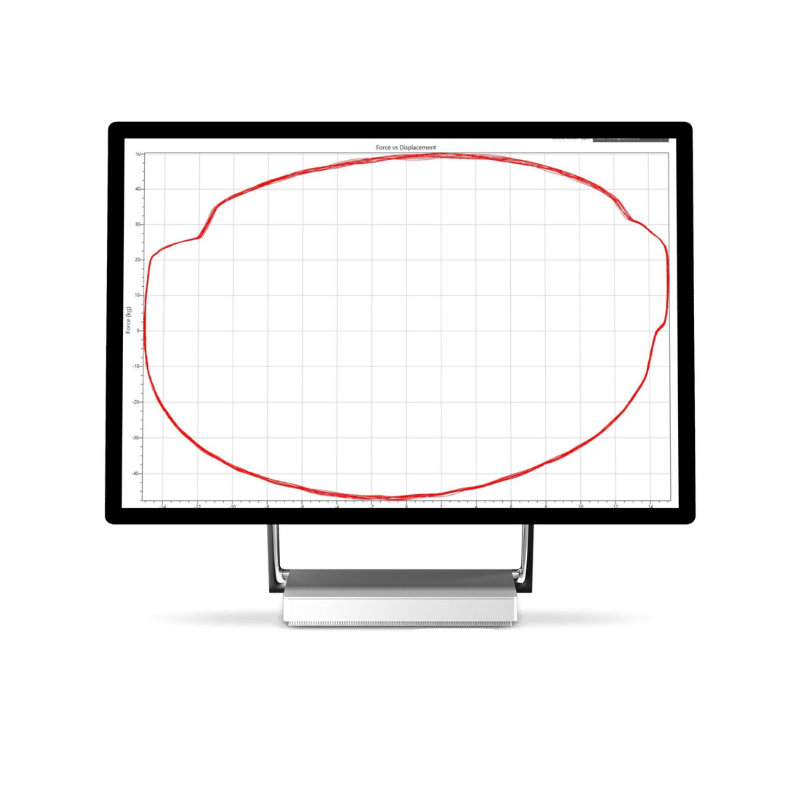

For shock dyno operators, Force Vs. Displacement graph probably is the most interesting of all. It shows the full motion of the shock absorber and can help identify the majority of the potential issues.

In Force Vs. Displacement graph the force is shown on the vertical axis and displacement – on the horizontal. The graph portrays the force a shock generates when it travels through its motion in both the compression and rebound damping phases.

This graph is mostly used to diagnose the health and consistency of a damper and should be treated as the most important graph.

Example of a good dyno graph

The image below displays Force Vs. Displacement graph of a healthy shock absorber. When analyzing this graph, we want to see a smooth consistent line forming an oval or circle.

Example of a bad dyno graph

If the graph has any major downward/upward peaks or drop-offs this shows that there is a drop in damping force and that the damper becomes less effective during that stroke.

Inconsistencies in the graph can arise from various factors. For example, it can happen due to mechanical wear or loose components within the shock absorber, as well as oil cavitation. Another critical aspect to consider is nitrogen pressure. Incorrect pressure levels can lead to inconsistent forces.

It is important to note that there are exceptions to the presence of upward peaks on the graph. This usually concerns shocks with internal/external bypass valves or hydraulic bump and rebound stoppers. When running a dyno, you will see a sudden rise of damping force in compression and that is OK.

Progress tracking

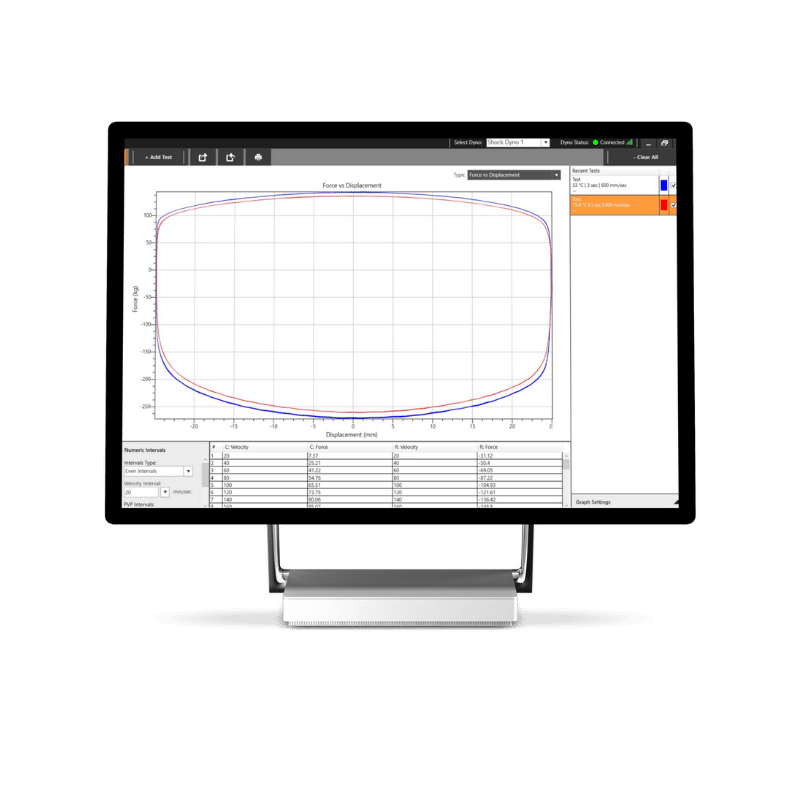

The data logger samples data on shock absorber performance tens of thousands of times per second. It allows for our software to show exactly where malfunctions occur in the shock’s stroke cycle. Moreover, users can compare graphs before and after repair with a few mouse clicks.

The graph changes when the oil temperature rises

LABA7 software does not average the force versus displacement graph into one graph. Instead, it presents them with hysteresis, allowing for the tracking of shock consistency even as the oil temperature rises.

When to use the Force versus Displacement graph

- Use the graph when building, servicing, or tuning a shock absorber to diagnose if it performs within proper tolerances.

- Compare graphs before and after shock rebuild or after revolving.

- See the live temperature of the shock and how it changes during the test.

Force vs. Velocity

When you are building, servicing, or tuning a shock, it is very important to know how to read velocity graphs. It helps you to determine the quality of the tested shock. In this and the following sections, you find velocity graphs explained in detail.

So, what does it show? As the dyno runs through a series of velocities, it records and plots the force corresponding to each velocity.

LABA7 software generates a Force vs. Velocity graph that shows the force on the vertical axis and the velocity on the horizontal axis. The shape of the curve allows you to assess the shock’s quality.

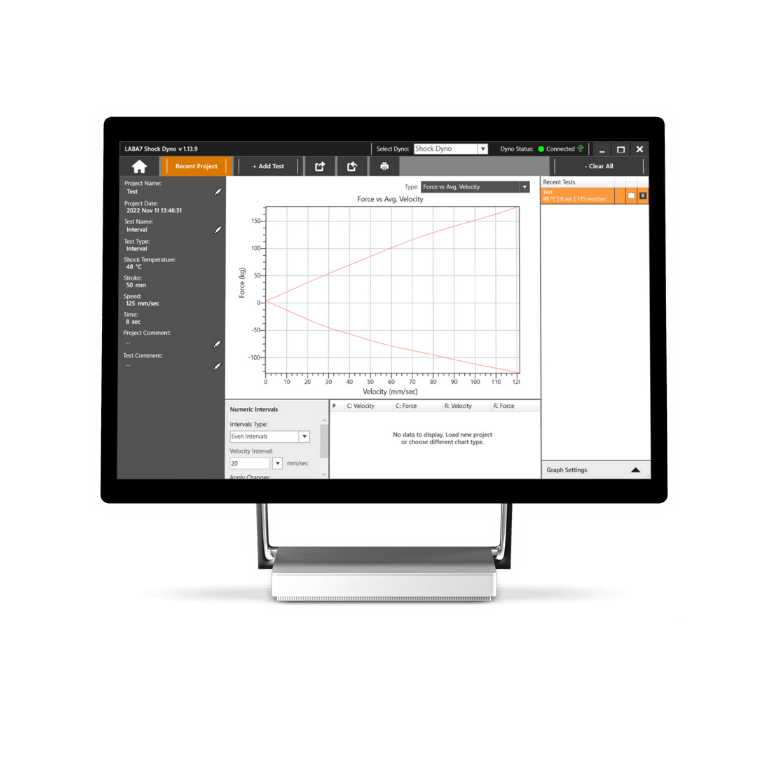

A well-constructed shock will produce a curve with a very little hysteresis gap between the “compression-acceleration/deceleration” and “rebound-acceleration/deceleration” portions of the curve. The image below demonstrates it.

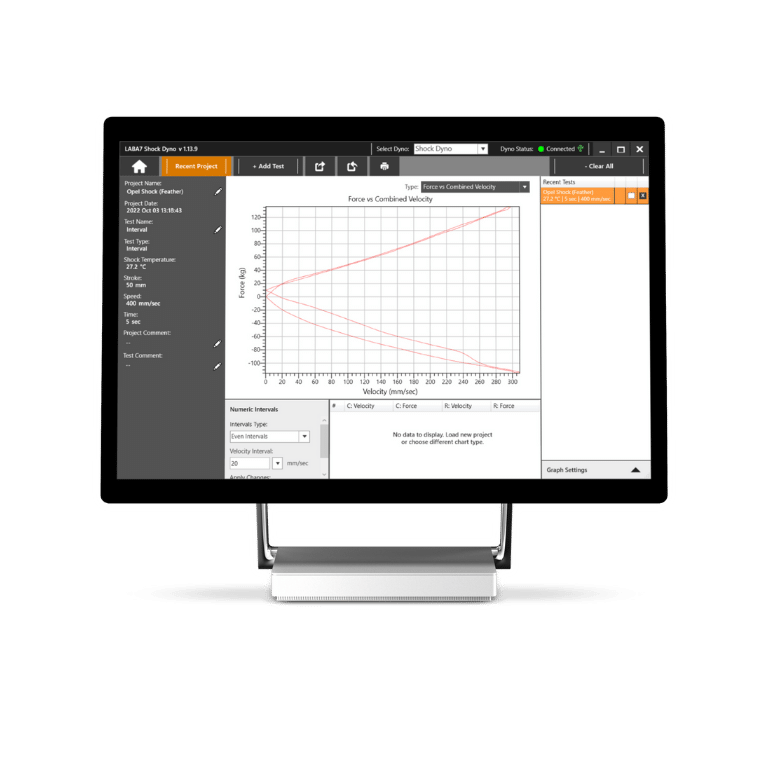

LABA7 software allows you to see a combined force vs velocity graph. This feature comes in handy when the hysteresis of forces is big and there are too many lines in the graph.

However, not all shocks will give you a nice force vs velocity graph. As you can see in the image below, this shock absorber is not in great shape.

Force vs. Avg. velocity

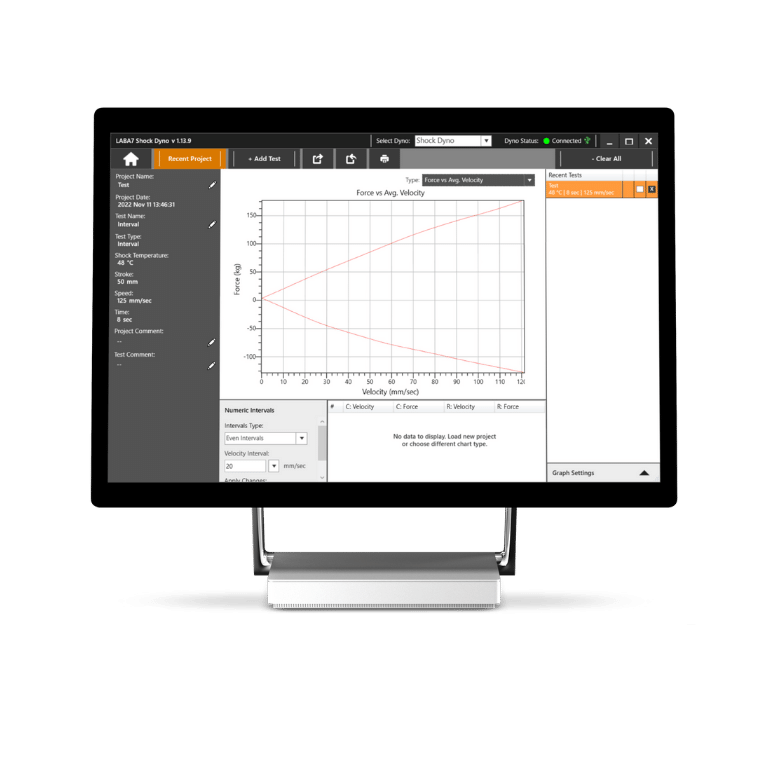

The Force vs. Avg. velocity graph takes the F/V “loop” and averages the accelerating and decelerating forces to produce a single line for each velocity data point. It should look similar to this graph.

This graph serves multiple purposes. It allows comparison of different shocks, analyzing the impact of adjusters or valving modifications, and ensuring proper matching of shocks between the left and right sides.

When examining it, it is essential to ensure that the hysteresis gap on the Force vs. Velocity graph is narrow. It ensures the validity of the Force vs. Avg. velocity graph for these applications.

However, beware of shocks with distorted Force vs. Velocity graphs! In such a case, the Force vs. Avg. velocity graph will hide underlying faults or issues within the shock.

That is why we highly recommend analyzing both velocity graphs when testing and diagnosing a shock absorber.

When to use Force vs. Avg. velocity graph:

- When comparing shock absorbers to one another.

- Track and understand the effects of adjusters or valving changes.

- Match shocks left to right.

PVP (Peak Velocity Plot)

The Peak Velocity Plot is also called a Peak Force-Velocity graph. It is useful for setting up dampers or comparing the main force they generate.

Here’s what you need to know:

- The graph shows the relationship between the maximum speed of the damper and the force it produces at that speed.

- However, remember that there is only one data point for each peak speed. This means we only record the force when the damper reaches its highest speed during the test.

- To create a full picture of the force generated by the damper at different speeds, we need to run multiple tests at increasingly higher speeds. By doing this, we can gather data points at different velocities and construct a curve that shows how the force changes as the speed of the damper increases.

The Peak Force-Velocity graph helps us understand how the force produced by a damper changes as its speed increases. To get a complete picture, we need to conduct several tests at different speeds and use the data to create a curve that shows the relationship between speed and force.

Force vs. Time

A force vs time graph can be useful when you only want to see force measurement. It eliminates any data inaccuracies caused by the position sensor. Also, this graph is provided with less “smoothing” algorithms.

In this graph, you will be able to see even the smallest force fluctuations.

Why Shock Dyno Graphs Matter?

Shock dyno graphs provide essential data for anyone looking to fine-tune suspension setups. They help:

- Identify performance inconsistencies

- Optimize damping characteristics for specific conditions

- Compare different shock settings

- Diagnose mechanical issues before they become performance problems

- Improve R&D efficiency by providing repeatable, data-driven results

How to Use Shock Dyno Graphs for Better Performance?

- Before making any changes to shock absorbers, run initial tests to establish a baseline.

- Test shocks with various settings and compare graphs to find optimal damping curves. Using LABA7 shock dyno software, it is very easy to do, as it’s shown in this video.

- Use a temperature graph to track to ensure consistent performance and repeatable results.

- Make informed adjustments to damping rates based on graph insights, rather than relying on trial and error.

- Investing in a high-quality shock dyno, such as LABA7’s models, ensures accurate data for better decision-making.

Conclusion

Understanding shock dyno graphs is essential for optimizing suspension performance, whether for racing, off-road applications, or everyday use. These graphs provide key insights into damping behavior, helping engineers, tuners, and mechanics fine-tune shock absorbers for maximum efficiency and consistency. By leveraging shock dyno data, you can make precise, informed adjustments that translate to better ride quality, improved handling, and overall enhanced vehicle dynamics.

For more insights into suspension testing and shock dyno technology, visit our website or contact our team of experts.

—

Thank you for visiting this article about how to read shock dyno graphs successfully!

You also might like these articles: