A vacuum bleed pump is crucial for removing air bubbles from the shock absorber fluid. Proper usage guarantees a high vacuum density and a quality oil fill, both pivotal for achieving optimal shock performance.

At LABA7, our line of vacuum bleed machines is designed to be fully automatic, offering a user-friendly experience while consistently delivering reliable results. In this guide, we will introduce you to the technology itself and help you learn how to use a vacuum bleed pump.

Table of contents:

- What is a shock vacuum bleed pump?

- Overview of LABA7 vacuum bleed pumps

- How to use a vacuum bleed pump

- Bottom line

What is a shock vacuum bleed pump?

A shock vacuum bleed pump is one of the most essential tools for shocks that optimizes the process of maintaining and enhancing the performance of dampers and forks in various vehicles such as cars, trucks, or bicycles. This device helps in filling shock absorbers while ensuring that there are no bubbles of air left in the oil chamber.

During the shock bleeding process, a vacuum bleed machine creates a vacuum inside the shock absorber and starts to fill in the suspension oil while eliminating any trapped air that comes from a bottle of fluids you’ve used. The bubble-free oil fluid is crucial for foaming prevention and retaining consistent suspension system performance in the long run. Meaning, you can avoid such issues as suspension sagging.

At LABA7, we have three different vacuum bleed pumps for shocks and forks – it’s the MODULE, DAILY, and PRO models. The core set of features is the same from device to device; however, they’ve been designed to fit different needs. When developing them, we aimed to build a technology that could create a deeper vacuum in order to eliminate trapped air from the oil most efficiently.

Overview of LABA7 vacuum bleed pumps

Each LABA7 vacuum bleed pump is fully automated, ensuring you can bleed dampers or forks using safety-friendly vacuum levels, which is virtually impossible with manual vacuum bleeder pumps. Nevertheless, each of our pumps has been developed for different use cases, differentiating in certain technical aspects.

If you haven’t decided what device you need yet, continue reading to learn more about LABA7 vacuum bleed pumps and make an informative decision:

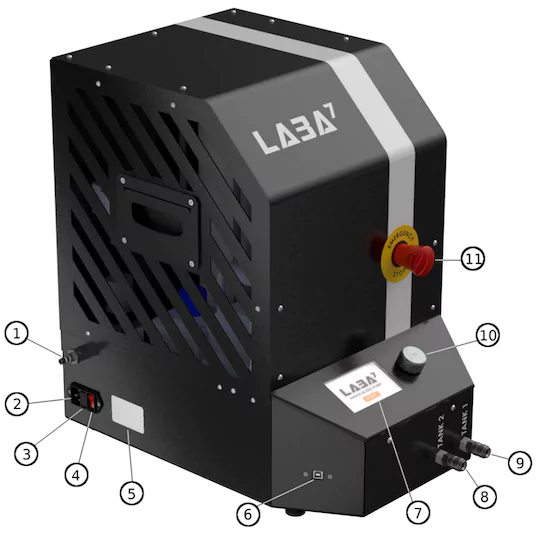

LABA7 Vacuum bleed pump MODULE

The LABA7 MODULE vacuum bleed machine is the most compact option on the list. It makes a perfect fit for trucks or vans that are always on the move and need to refill their shock absorbers on the way.

- Compressed air connector.

- Power cable connector.

- Fuse.

- Power switch.

- Label.

- USB connector.

- External tank 1 hose connector.

- External tank 2 hose connector.

- External tank 1 cable connector.

- External tank 2 cable connector.

- Emergency stop button.

- 4.3″ LCD display.

- Main control button.

Vacuum Bleed Pump MODULE Technical Specifications

And these are the vacuum bleed pump MODULE technical specifications:

| Vacuum bleed pump MODULE | |

| Fully automatic | Yes |

| 8 custom presets | Yes |

| Internal tanks | No |

| Works with external tanks | Yes |

| Two filling modes | Bladder shock and separating piston |

| Adjustable pressure | 0.5 – 4 BAR |

| Adjustable vacuum | -0.3 – -0.99 BAR |

| Dimensions | 260 x 271 x 343 mm |

| Price | 2500 € |

It’s important to note that the MODULE option doesn’t have internal tanks; therefore, you’d need to get an external vacuum bleed pump additionally, which we will talk about below.

Vacuum bleed pump DAILY

The LABA7 vacuum bleed pump DAILY speaks for itself – it’s the middle option between the MODULE and PRO models, which can benefit any vehicle service business. The device is capable of filling two dampers simultaneously; therefore, you will be able to complete the work in no time.

- Compressed air connector.

- Power cable connector.

- Fuse.

- Power switch.

- Label.

- USB connector.

- 4.3″ LCD display.

- Tank 2 connector.

- Tank 1 connector.

- Main control button.

- Emergency stop button.

Vacuum Bleed Pump DAILY Technical Specifications

Now, let’s delve into the technical specs of the LABA7 DAILY pump option:

| Vacuum bleed pump DAILY | |

| Fully automatic | Yes |

| 8 custom presets | Yes |

| Internal tanks | Yes, two |

| Works with external tanks | No |

| Two filling modes | Bladder shock and separating piston |

| Adjustable pressure | 0.5 – 3 BAR |

| Adjustable vacuum | -0.3 – -0.99 BAR |

| Dimensions | 333 x 497 x 478 mm |

| Price | 2950 € |

LABA7 Vacuum Bleed Pump PRO

The PRO vacuum bleed shock is the most advanced option for any vehicle professional. With an external tank connected, it can fill up to even three dampers at a time.

- Compressed air connector.

- Power cable connector.

- Fuse.

- Power switch.

- Label.

- USB connector.

- 4.3″ LCD display.

- Main control button.

- Emergency stop button.

- External tank cable connector.

- External tank hose connector.

- Internal tank 1 connector.

- Internal tank 2 connector.

Vacuum Bleed Pump PRO Technical Specifications

Here, you can also find the technical features of the LABA7 PRO bleed machine:

| Vacuum bleed pump PRO | |

| Fully automatic | Yes |

| 8 custom presets | Yes |

| Internal tanks | Yes, two |

| Works with external tanks | Yes, optional |

| Two filling modes | Bladder shock and separating piston |

| Adjustable pressure | 0.5 – 4 BAR |

| Adjustable vacuum | -0.3 – -0.99 BAR |

| Dimensions | 411 x 497 x 551 mm |

| Price | 4000 € |

LABA7 Manual Vacuum Bleed Pump

The Manual vacuum bleed pump is the entry-level option for workshops and enthusiasts seeking reliable shock bleeding without electronic complexity. It can fill up to two dampers at a time using precision valves and gauges.

- Compressed air connector.

- Power switch.

- Fuse.

- Power cable connector.

- Tank 2 connector.

- Tank 1 connector.

- Pressure control knob.

- Vacuum control knob.

- Vacuum pump switch.

- Vacuum / pressure gauge.

- Tank 1 oil level indicator.

- Tank 2 oil level indicator.

Manual Vacuum Bleed Pump Technical Specifications

LABA7 Vacuum Bleed Pump MANUAL

Here, you can also find the technical features of the LABA7 Manual bleed machine:

| Vacuum Bleed Pump Manual | |

| Fully automatic | No |

| Custom presets | No |

| Internal tanks | Yes, two 2-liter |

| Works with external tanks | No |

| Filling modes | Standard vacuum bleed |

| Adjustable pressure | 0.5 – 3 BAR |

| Adjustable vacuum | Up to -0.99 BAR |

| Dimensions | 390 x 360 x 400 mm |

| Price | 1800 € |

Manual Vacuum Bleed Pump technical specifications

External vacuum pump tank

An external vacuum pump tank comes in handy when you’re using the MODULE or PRO vacuum bleeders, as well as if you must work with several different types of oil at once, as an external tank allows you to do it without needing to clear out the tank.

You can choose between two sizes of LABA7 external vacuum pump tank, with either a 3L (287 x 577 x 284 mm) or a 6L tank (225 x 537 x 250 mm):

- Hose connector.

- Cable.

- Filling connector.

How to use a vacuum bleed pump

Whether you’ve already purchased a vacuum bleed pump or are still considering doing that, learning how to use it properly is essential for ensuring optimal results and keeping your shock absorbers well-maintained.

Below, you will find a constructive guide on how to use a vacuum bleed pump, the steps apply no matter if it’s the LABA7 MODULE, DAILY, or PRO model. For more extensive guidance, make sure to download a dedicated manual.

Before You Start: Air Supply & Power Requirements

Before you begin using your LABA7 vacuum bleed pump, it’s essential to ensure that your workspace meets the necessary air supply and electrical power requirements. Proper setup from the start will guarantee optimal performance and prevent potential damage to your equipment.

Air Compressor Requirements

Each LABA7 vacuum bleed pump model has specific compressed air requirements:

- MODULE: Requires a minimum of 4 bar (58 PSI) pressure rating

- DAILY: Requires a minimum of 3 bar (43.5 PSI) pressure rating

- PRO: Requires a minimum of 4 bar (58 PSI) pressure rating

- MANUAL: Requires a minimum of 3 bar (43.5 PSI) pressure rating

All models require air quality that meets ISO 8573 standards. This international standard ensures your compressed air is free from contaminants such as water vapor, oil, and particulate matter that could interfere with the vacuum bleeding process or damage internal components.

Why Air Quality Matters

Using compressed air that doesn’t meet ISO 8573 standards can lead to moisture contamination in your shock oil, reduced vacuum efficiency, and premature wear on pump components. Invest in proper air filtration and ensure your compressor delivers clean, dry air.

Electrical Power Setup

Verify that your electrical outlet matches the voltage requirements specified on your device’s label. Each pump comes with a dedicated power cable designed for safe operation. Always use the included cable and ensure your power source provides a stable electrical supply to prevent interruptions during the bleeding process.

Launching a shock bleeder

Before moving further, note that each suspension vacuum bleed machine requires a different bar pressure rating and air quality for a vacuum bleed pump to work:

- Vacuum Bleed Pump MODULE – minimum 4 bar pressure rating and air quality according to ISO 8573

- Vacuum Bleed Pump DAILY – minimum 3 bar pressure rating and air quality according to ISO 8573

- Vacuum Bleed Pump PRO – minimum 4 bar pressure rating and air quality according to ISO 8573

- Vacuum Bleed Pump MANUAL – minimum 3 bar pressure rating and air quality according to ISO 8573

If you have checked the power supply rating for it to fit the device and have everything else set, continue reading and find the steps for launching LABA7 bleed machines for the first time:

- Connect an air compressor air hose to the compressed air connector.

- Connect the included power cable to the device’s power connector and plug it into the electrical outlet.

- Turn the shock bleeder power switch on for the green light to enlighten.

- Wait for 2 seconds for the pump to initialize.

- Press “OK” to start.

Setting up a shock bleed pump

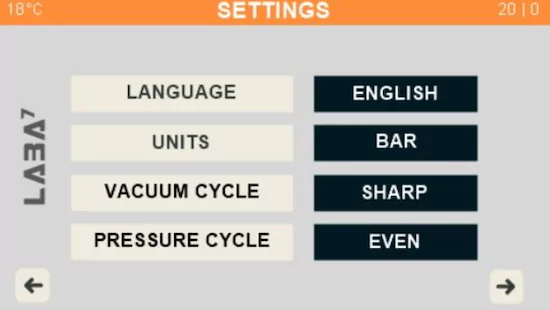

After you have launched your suspension vacuum bleed machine for the first time, it’s time to configure it. You will see all the settings options on the LCD screen on a shock bleed pump and manage them using the main control button.

Continue with the steps below:

- Scroll to the SETTINGS option and press OK.

- Select one of the setting options by clicking OK to enter the Edit mode.

- Rotate the main button to change the selection and press OK to save the modification.

- Move to the NEXT button and click OK to enter the second page of the SETTINGS menu.

- Repeat step 3 for modifying a selected setting.

- Move to the following settings page and choose one of the eight templates

- Click OK to edit the selected template.

Shock bleeding and filling (bladder shock and separating piston)

LABA7’s bleed machines are compatible with both bladder shocks and shocks with separating pistons. If you are using a vacuum bleed pump for the first time, we suggest using the automatic mode to bleed and fill your shock. This will help you avoid human error and achieve desired results effortlessly.

Below, we will guide you through how to bleed and fill both types of shocks using an automatic mode.

Bladder shock:

- Connect the hose to the pump connectors of the TANK 1 and/or TANK 2.

- Attach the necessary shock bleed connector to the opposite end of the hose.

- Select the BLEED SHOCK option from the main window.

- Select the BLADDER SHOCK option from the BLEED menu.

- Choose the AUTOMATIC BLEED option from the INTERVALS menu.

- Connect the shock absorber to the bleed connector that is attached to the hose.

- Ensure that the shock being bled is positioned below the External Tank, with the bleed port oriented upward.

- Select the confirmation icon to start the bleed process.

- Allow the shock absorber to fill automatically, or stop the filling process at any point by pressing the back button and choosing the confirmation icon.

Shock with a separating piston:

- Connect the hose to the pump connectors of the TANK 1 and/or TANK 2.

- Connect the necessary shock bleed connector to the opposite end of the hose.

- Choose the BLEED SHOCK option from the main window.

- Select the SEPARATING PISTON option from the BLEED menu.

- Select the AUTOMATIC BLEED option from the INTERVALS menu.

- Connect the shock absorber to the bleed connector that is attached to the hose.

- Make sure that the shock being bled is placed below the External Tank, with the bleed port positioned upward.

- Choose the confirmation icon to start the bleed process.

- Wait for the shock absorber to complete filling, or halt the filling operation at any moment by pressing the back button and choosing the confirmation icon.

Bear in mind to open all external adjusters on the shock absorber, push the separating piston to the bottom, and install the circlip (fastener) to prevent the free piston from shooting out when filling.

Safety & Best Practices

Proper preparation of your shock absorber is critical for safe and effective bleeding. Follow these essential steps before starting the vacuum bleed process.

Prepare External Adjusters

Always open all external adjusters on the shock absorber before beginning. This prevents dangerous pressure buildup inside the shock during the bleeding and filling process, ensuring fluid can flow freely without resistance.

Secure the Separating Piston

For shocks equipped with separating pistons, push the piston all the way to the bottom of its travel before connecting to the bleed pump. This creates proper clearance for oil filling and prevents air pockets from forming.

Install the Circlip (Critical Safety Step)

After positioning the separating piston at the bottom, install the circlip (fastener) securely. This small component is essential—it prevents the free piston from violently shooting out under pressure during the filling operation, which could cause serious injury or equipment damage. Never skip this step.

Additional Safety Reminders

Position the shock below the external tank with the bleed port facing upward. Wear safety glasses and gloves when handling suspension oils. Inspect all hose connections before starting, and keep the emergency stop button within easy reach throughout the operation.

Is it worth getting a shock absorber vacuum bleed pump?

When questioning whether getting a shock absorber vacuum bleed pump is worth it, it’s always important to evaluate your intentions and determination to maintain the quality of the suspension systems you work with.

But to also help you get a better image, we’ve compiled a list of the vacuum bleeder pump benefits:

- Efficient gas removal from the oil chamber. Each new bottle of suspension oil can average around 10% gas dissolved in the liquid. With the help of a shock vacuum pump, you can securely reduce the amount of gas in the damper to a minimum.

- Security-friendly vacuum pressure adjustment. By using an automatic shock bleeder, you can adjust the pressure of a vacuum, which allows you to bleed vacuum-sensitive suspension system parts risk-free.

- Enhanced vehicle performance. Using an automatic vacuum bleed pump for shock absorbers ensures perfect vacuum and pressure levels that in turn reduce the chances of aeration and cavitation effects forming.

- Possibility to serve several shocks simultaneously. With LABA7 vacuum bleed pumps, you can bleed and fill several dampers at a time. Hence, you will not only save time but also boost your income.

- User-friendly experience. Bleeding and filling shock absorbers or forks manually requires technical knowledge and can be challenging for beginners. The LABA7 suspension vacuum pump parts are fully automatic, making it a great option for users with no prior experience.

Bottom Line

Mastering the use of a vacuum bleed pump is essential for maintaining optimal shock absorber performance and extending the life of your suspension systems. Whether you choose the compact MODULE, the versatile DAILY, the advanced PRO model, or the entry-level MANUAL, LABA7’s vacuum bleed pumps simplify what was once a technically challenging process.

Take the time to familiarize yourself with your specific model’s features, practice the procedures outlined in this guide, and always prioritize safety. The result will be perfectly bled shock absorbers that deliver the smooth, controlled performance your customers expect.

FAQ About LABA7 Vacuum Bleed Pumps

Do I need an external tank with every LABA7 pump?

No. The DAILY model comes with two internal tanks and doesn’t support external tanks. The MODULE requires external tanks as it has no internal tanks. The PRO includes two internal tanks but can optionally connect to external tanks for filling up to three dampers simultaneously.

What vacuum/pressure ranges do LABA7 pumps support?

All LABA7 vacuum bleed pumps support adjustable pressure from 0.5 to 5 BAR and adjustable vacuum from -0.3 to -0.99 BAR. These ranges ensure safe, controlled bleeding for various shock absorber types.

Can LABA7 bleed both bladder and separating piston shocks automatically?

Yes. All LABA7 models (MODULE, DAILY, and PRO) feature automatic bleeding modes for both bladder shocks and shocks with separating pistons, making the process effortless and error-free.

What air supply do I need for stable operation?

The MODULE and PRO require a minimum of 5 bar pressure rating, while the DAILY needs at least 3 bar. All models require compressed air quality that meets ISO 8573 standards to ensure clean, dry air free from contaminants.

You also might like these articles:

- Finding the best shock dyno for sale

- How to use a spring dyno

- How to use racing scales

- How to use a shock dyno

- The Ultimate Guide to Suspension Vacuum Pumps: Everything You Need to Know

- How to Bleed Shocks: A Manual vs Automatic Showdown

- Testing shock absorbers after Manual vs Automatic damper bleeding