Automatic Spring Tester for Any Spring

Our fully automatic spring rate tester measures fork and shock absorber spring rates with precision. Monitor test results instantly with wireless data transmission and real-time performance analytics.

Spring rate tester MINI

Spring rate tester DAILY

Spring rate tester PRO

No More Limits – Spring Dyno Adapters for Spring Testers

Focusing on versatility, we supply a range of adapters for our spring rate testers. Their range covers any type of vehicle from MTBs to 4x4s: motorcycles, circuit racing, and dirt track racing vehicles.

*Adapters are not compatible with the Spring tester PRO.

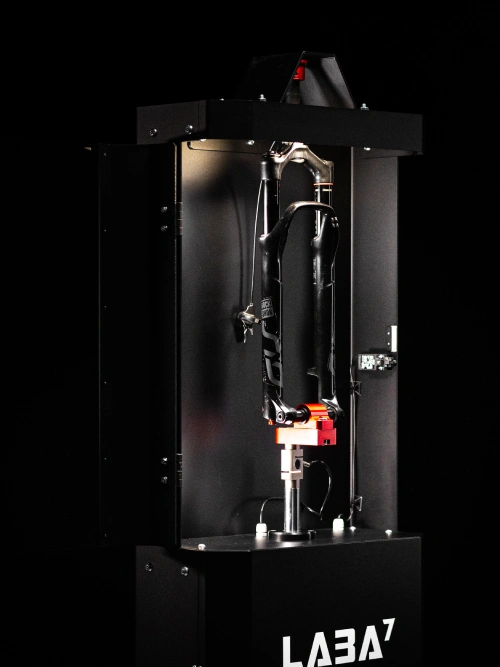

Shock Spring Testers for Workshops

LABA7 develops professional spring testing machines for workshops, spring manufacturers, and motorsport teams worldwide.

Our equipment makes spring rate testing simple and accurate. Each spring rate tester is designed to be very easy to use and provides the most accurate results immediately on the screen of your device, whether testing fork springs, air springs, bump stops, or gas pressure systems.

Accurate Spring Rate Dynamometers by Design

LABA7 spring rate dynos not only allow you to adjust stroke and speed, but are developed to be accurate and precise from the ground up.

Perfect spring rate testing requires extremely slow linear motion. Our spring testers use mechanical motors that compress springs vertically at a rate of up to 5 mm per second. This ensures the collection of the most reliable data.

The load cell in the LABA7 spring load tester equipment is positioned on top of the vertical shaft. This solution drastically improves accuracy by eliminating friction caused by the bushing.

Key Features & Benefits of LABA7 Spring Testing Machines

Technical Features

Fully Automatic

As with all LABA7 equipment, our spring testers are built with simplicity in mind. Place a spring, fork, or bump stop into the machine, select the settings, and the test will run automatically. Analyze performance through the force-displacement graph and spring progressiveness measurements.

Wireless Connectivity

Connect the spring rate tester to your device via local Wi-Fi network or USB cable. Both options allow you to track performance data in real-time.

Safety

During the spring rate test, springs are subjected to tremendous force. In case of spring failure, the outcome can be dire. To protect operators and workshops, LABA7 spring rate dynos feature Plexiglass shields and steel casings for maximum safety.

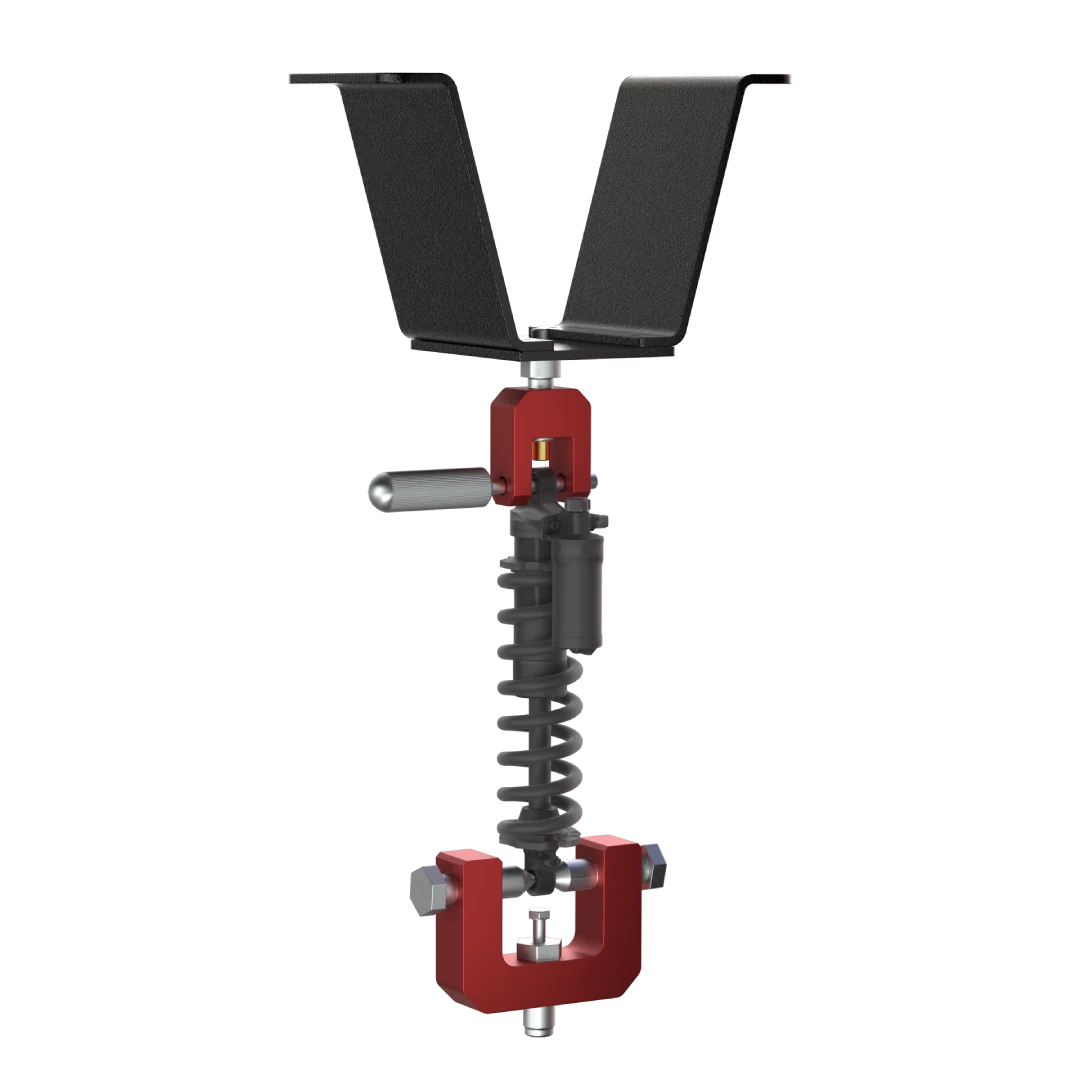

MTB and Motorcycle Fork Adapters

To meet diverse customer needs, LABA7 spring testers come equipped with special adapters for MTB and motorcycle forks. Self-preload clevis and U-shaped mounts for rear shocks feature protective plastic heads to prevent damage to tested units.

Custom Mounting Solutions

Testing springs, forks, or coils of unconventional sizes? We develop custom mounts for specialized applications. Contact us for more information.

Seal Drag Testing

Our spring compression testers also function as spring tension testers for seal drag testing. This test measures the force required to move suspension components while maintaining proper sealing to prevent contamination – a crucial factor in ensuring the longevity and proper function of the suspension system.

Benefits of the LABA7 Spring Rate Tester

Know Your Springs

Measure the exact force created by springs, forks, and coils. Since there’s no universal measurement protocol, every manufacturer measures differently. Some use preload, others don’t – causing declared spring rates to vary. Knowing the precise spring rate helps you choose the right spring based on the athlete, bike, or vehicle weight.

Test Bump Stops

The LABA7 spring rate dyno also measures bump stop force. Bump stops prevent suspension damage, maintain consistent handling, and absorb vibrations for smoother rides. This testing ensures optimal bump stop selection for your application.

Measure Air Springs

Test the real force created by the air springs of MTB and motorcycle forks.

Measure Bearing Friction

Using our spring rate dyno, you can measure and evaluate the force differences between individual bearings. Manufacturers of shock absorbers, forks, and coils pay close attention to friction because it creates an unwanted and uncontrolled force. The LABA7 spring rate tester enables you to select seals that create the least friction and increase the efficiency of your suspension.

Reports and Labels

If you are working with many different springs, forks, and coils, our spring-testing machines can help to mark them quickly. Print the report label with spring force after the test, which includes the force generated in kN.

LABA7 Spring Dyno Software

Our intuitive spring testing machine software provides comprehensive analysis tools:

More LABA7 products:

Shock dynos

Vacuum bleed pumps

Race car scales

Suspension tools

Frequently Asked Questions about Spring Rate Tester

Why is it important to test springs?

Even identically looking springs can perform differently due to variations in materials and manufacturing processes. Testing ensures you’re using the correct spring rate for your specific application.

How does spring testing benefit riders and drivers?

For riders, spring rate testing ensures you’re using the right spring for your weight, optimizing suspension performance. For drivers, it allows you to fine-tune vehicle performance by selecting the ideal spring for each corner of the car.

Can this equipment test coil springs?

Yes, our spring rate testers function as a comprehensive coil spring tester, handling all types of automotive and motorcycle coil springs.

Can this equipment perform spring tension testing?

Yes, our spring rate tester capabilities allow you to measure both compression and tension forces. As a complete testing machine, it measures seal drag and the force required to extend springs.

How are spring rates measured?

Traditional testing requires manual compression and force calculations to determine the spring rate. With the LABA7 spring rate tester, simply insert your spring, press start, and receive instant, accurate measurements on your screen for professional testing accessible to any workshop.

Can the tester be used as a spring smasher for heavy-duty testing?

Yes. The LABA7 tester can apply controlled force to simulate extreme compressions, effectively working as a spring smasher. This allows workshops and racing teams to evaluate how springs perform under aggressive loads as well as in precise, slow-rate testing.