Electromagnetic damper test system – EMA

EMA by LABA7 comes feature-rich and brings jaw-dropping specs. We developed our electromagnetic damper test system to deliver remarkably accurate results at an affordable price.

One standard of precision. Four levels of power.

30 kW

60 kW

90 kW

120 kW

* Depends on the damper. Depends on the stroke.

Standard features of all EMAs

Sampling rate and accuracy

Digital position sensor that samples data at a frequency of 20 kHz with an accuracy of 50 nm. To ensure there is no phase shift in the data, we simultaneously read force measurements at the same 20 kHz speed using an analog sensor.

Inputs for analog sensors

All EMAs come with three more inputs capable of sequentially reading other analog sensors at 20 kHz for comprehensive testing. Additional channels allow to monitor pressure, temperature, acceleration, noise, and other important factors at the same time.

Noise levels

On standby, EMA produces around 55 dB of background noise. When electromagnetic actuators are activated the noise levels depend on the velocity of the test. They range from as low as 60 dB. This makes EMA an ideal solution to test suspension components for any EV.

Custom applications

In-house developed components allow us to have full control of compatibility and upgradability. Not to mention it opens opportunities to innovate and create 100% custom features.

What makes EMA special?

Components developed in-house

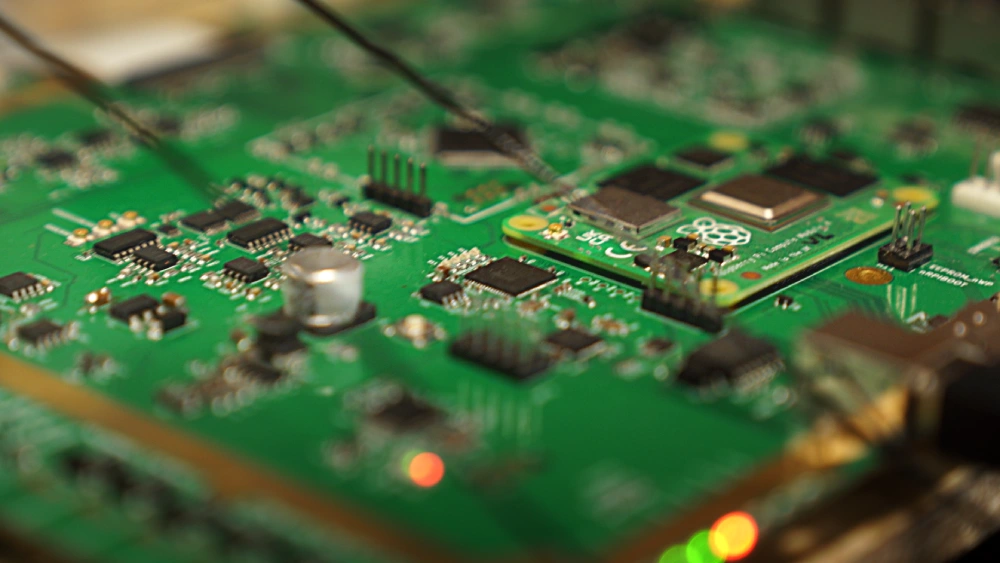

Data logger

The data logger for EMA is a marvel. Our engineers developed it in-house with the sole objective of detecting even the tiniest force changes in damper performance.

It delivers an impressive position resolution of 50 nanometers and a sampling rate of 20 kHz. The load cell resolution and sampling rate are equally impressive of 20-bit and 20 kHz.

Our data logger supports multiple analog output and input channels to maximize versatility of the machine.

Control unit

The control unit of EMA is integrated with a data logger into a single board. This solution allows us to provide the most accurate test results in real time.

Incorporating state-of-the-art technologies such as silicon carbide (SiC) MOSFETs allowed us to generate significantly more power at a fraction of the cost.

Additionally, this unit controls the operation of the smart power supply, enhancing the efficiency of EMA by LABA7 while reducing energy consumption.

Power unit

The smart power supply unit of the EMA is the first and, to date, the only such solution on the market. The high-voltage power supply to the actuators, facilitated by supercapacitor packs, eliminates the dependency on high-voltage and amperage input. This innovation eliminates the need for high-power input and opens possibilities for suspension workshops, motorsport teams, or R&D labs to utilize electromagnetic linear shock dynos for the first time. Even on a trackside!

EMA operates from a 3-phase 380/400 VAC 16 A, but all models can be optimized to run from a standard 1-phase 220/240 VAC socket on request. Other power input configurations, for example, mono-phase 110/120 VAC, are also available. Contact us to learn more.

In addition, the unit stores electrical power. This reserve allows tests to continue and be completed even during power shortages.

Software

LABA7’s software for electromagnetic damper test systems is designed with user experience in mind. Operators can easily find, manage, and customize the features of the tests, minimizing the onboarding time.

Our software for EMA allows pre- and post-test editing of data. To save time, it enables operators to trim track data and test damper performance in specific stages of the course. After the test, operators can slide and cut graphs as well as push individual cycles on top of each other for better data analysis.

The software enables seamless integration with additional sensors and testing equipment.

Advantages of LABA7 shock dynos

Repeatable results

The LABA7 electromagnetic shock dyno ensures consistently repeatable results, providing confidence in every test conducted.

Low maintenance

EMA requires minimal maintenance as it has only a few mechanical components, thus guaranteeing longevity and operational efficiency.

High efficiency

EMA employs a smart power supply system enabling it to conduct damper tests at a staggering velocity of 7 m/s, all while maintaining a modest power consumption rate.

High performance

EMA combines high force, immediate acceleration, and remarkable speed with a data logger that provides unprecedented data precision and depth.

Versatility

LABA7 electromagnetically actuated damper test system produces a comprehensive range of waveforms, encompassing sinusoidal, triangular, impulse, sine-on-sine, and custom.

Expand your possibilities with shock dyno adapters

LABA7 shock dyno adapters create a seamless link, allowing for the most accurate and insightful tests of your shock absorbers. The result – enhanced performance, efficiency, and a deeper understanding of your equipment’s capabilities.

Electromagnetic vs Hydraulic damper testing systems

Electromagnetic and hydraulic damper test systems are two distinct technologies used to evaluate and test dampers in various applications.

Electromagnetic actuators provide high precision in force control with quick response times. They excel in handling a wide range of frequencies and operate quietly, thanks to fewer moving parts and the absence of fluid dynamics. Additionally, these systems require less maintenance and experience minimal downtime, making them highly efficient.

On the other hand, hydraulic damper testing systems are designed to generate the higher forces needed for testing large or industrial dampers. Especially in lower-frequency testing. However, hydraulic systems demand regular maintenance due to potential leaks, fluid replacement needs, and the wear and tear of mechanical components. Moreover, they have more stringent health and safety requirements for operators compared to electromagnetic test systems.

Unleash the power of your suspension

Performance comparison

Whether evaluating left versus right dampers, front versus back setups, or simply assessing different damper settings, our software offers seamless before-and-after visualizations. This feature is indispensable for showcasing improvements to clients during servicing or tuning sessions.

Diagnostics

Diagnose damper issues swiftly and accurately. LABA7 shock dyno software generates multiple graphs in real time, providing immediate insights into shock or fork behavior during compression and rebound. Whether it’s identifying blocked oil passages, broken shims, or cavitation due to insufficient gas pressure, our dyno graph swiftly pinpoints the root cause of any anomaly.

Ultra-fine tuning and adjustment

Navigate tuning and adjustment processes with ease. EMA replicates a wide range of waves and impulses bringing shock absorber testing as much to real-life conditions as it is possible. In addition to that the data is of extremely high accuracy, allowing you to make informed adjustments tailoring damper to individual preferences. By interpreting graphs alongside, you can ultra-fine-tune the suspension to meet even the most demanding requirements that translate into tangible on-track improvements.

Quality control and warranty

Ensure quality and uphold warranty standards through rigorous quality control measures. Before customer delivery, subject dampers to dyno testing to swiftly identify and rectify potential errors. This proactive approach guarantees customer satisfaction and minimizes the risk of warranty claims.