A revolution is quietly unfolding in the world of advanced shock absorber testing. While industry giants like Siemens and Aerotech have long dominated the landscape, LABA7 EMA has come to redefine the rules of the game. Our innovative electromagnetic actuator for damper testing challenges conventional wisdom with its cutting-edge in-house controller and data logger, coupled with a groundbreaking smart power supply system.

Imagine a system that can deliver staggering power outputs of 700V and 900A from a standard 380V 16A power source. Picture a controller that seamlessly integrates with a data logger, offering unparalleled precision down to 50 nanometers and lightning-fast 20 kHz sampling rates. Envision the freedom to upgrade and adapt your system without being shackled by third-party limitations.

This isn’t science fiction—it’s the reality LABA7 is bringing to the table. As we dive into the intricacies of the game-changing technology, prepare to discover how we are potentially leapfrogging the competition in ways that could reshape the future of shock absorber testing.

In-House Developed Controller and Data Logger

Future Upgrades and Development

Developing the controller and data logger in-house provides us freedom for future upgrades and development. Since LABA7 has complete control over the design and architecture, it can implement new features, enhance performance, and adapt the system to meet evolving needs without being limited by third-party constraints.

This flexibility is crucial for staying ahead in technology and responding to specific customer requirements. An in-house team can quickly iterate and improve the system based on user feedback and technological advancements, ensuring that the product remains cutting-edge and highly competitive. LABA7 EMA controller/data logger can easily implement the HIL testing method with delays as slow as 5 ms.

LABA7 EMA Data Logger and Controller

Combining the data logger and controller into a single unit offers significant benefits in terms of performance and reliability. It ensures that components are perfectly synchronized, reducing communication delays and potential data mismatches. It also simplifies the system architecture, leading to fewer points of failure and easier troubleshooting.

A unified system means that all data processing and logging occur within the same environment, enhancing data accuracy, repeatability, and consistency. This is particularly important in high-precision applications where even minor discrepancies can lead to significant errors.

In-House Data Logger vs. Off-The-Shelf Solutions

An in-house data logger, designed specifically to work with the LABA7 EMA controller, is inherently more optimized and reliable than an off-the-shelf solution. Generic data loggers might face compatibility issues, leading to suboptimal performance.

In contrast, an in-house data logger can be finely tuned to the specific requirements of the EMA system, ensuring seamless operation and optimal data acquisition. This bespoke design allows for better handling of the high-resolution and high-sampling rate demands typical of advanced shock absorber testing, providing more accurate and reliable data.

Main Differences Between LABA7 EMA Controller and Aerotech A3200

The LABA7 EMA controller and the Aerotech A3200 differ significantly in terms of design and application focus.

The LABA7 controller uses advanced Silicon Carbide (SiC) drivers, which offer higher efficiency, better thermal management, and faster switching capabilities compared to traditional silicon-based drivers. This leads to improved performance and reliability, especially in demanding applications.

Furthermore, the LABA7 controller features high-resolution (50 nanometers) and high-sampling rate (20 kHz) capabilities for both position and load cell measurements, ensuring precise and fast data acquisition. It also offers a wide range of versatile input and output options, including multiple high-resolution analog and digital channels, isolated and non-isolated interfaces, and specialized communication interfaces like CAN and RS485.

In contrast, the Aerotech A3200, while powerful and widely used, is designed as a general-purpose controller. When paired with off-the-shelf data loggers, it might face challenges in achieving the same level of integration and performance as the LABA7 system. The A3200’s performance may be limited by the separate data logger’s capabilities, leading to potential issues with synchronization, data accuracy, and overall system efficiency.

Smart Power Supply System

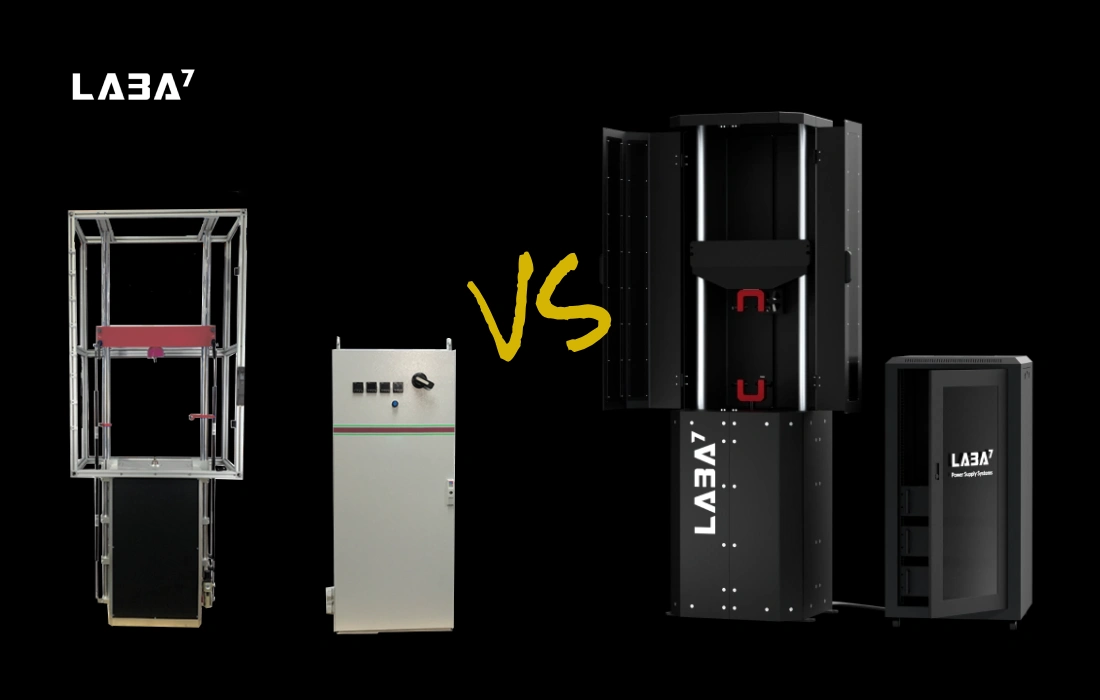

LABA7’s smart power supply system is innovative in using a standard 380V 16A power source to charge ~3F capacitor modules, which then supply power to actuators at 700V and 900A. This method offers several advantages over traditional systems that rely directly on high current draws from the main supply.

LABA7’s smart power supply system offers a superior alternative to traditional controllers from Siemens and Aerotech by leveraging capacitor-based energy storage to achieve high power outputs from a lower input current. This results in reduced infrastructure requirements, significant cost savings, enhanced reliability, and better performance.

For users looking for a flexible, cost-effective, and reliable EMA system, LABA7’s innovative approach provides compelling advantages.

Efficient Power Management and High Power Output

LABA7’s system efficiently manages power by using capacitors to store energy and release it as needed. This allows the system to achieve high power outputs (700V and 900A) from a standard 380V 16A input.

Traditional systems from companies like Siemens and Aerotech typically require direct high-current inputs (e.g., 380V 30A to 100A), which can strain electrical infrastructure and increase operational costs.

Reduced Infrastructure Requirements

By utilizing a standard 380V 16A supply, LABA7’s system significantly reduces the need for extensive electrical upgrades. Traditional systems from Siemens and Aerotech often necessitate robust electrical infrastructure to support high current demands, which can be costly and difficult to implement in many facilities.

LABA7’s approach offers greater flexibility and makes installation feasible in a wider range of environments, including those with limited electrical capacity.

Cost Savings

The smart power supply system from LABA7 EMA leads to substantial cost savings. It minimizes the need for expensive electrical upgrades and reduces operational costs through efficient power usage. In contrast, the higher current requirements of Siemens and Aerotech systems increase both installation and operational expenses. This makes LABA7’s system more economical for a broader range of users, including smaller facilities with budget constraints.

Enhanced Performance and Reliability

LABA7’s use of capacitors ensures stable and reliable power delivery, minimizing voltage drops and power fluctuations that can affect performance. This leads to consistent operation and can extend the lifespan of system components. Traditional systems, which draw high currents directly from the main supply, are more susceptible to power instability and may require more frequent maintenance.

Comparison with Siemens and Aerotech Controllers

Siemens Motor Controllers

Siemens offers a range of motor control centers (MCCs) and medium-voltage motor controllers, such as the SIMOVAC and SIMOVAC-AR. They support high voltage ratings (2.3 to 6.9 kV) and current ratings up to 720A. While these controllers are robust and suitable for high-demand applications, they require extensive electrical infrastructure and are less flexible in environments with limited power capacity.

Aerotech Controllers

Aerotech’s A3200 controller is a powerful motion controller. However, it typically requires higher current inputs and may not be as optimized for integrated power management as LABA7’s system. The need for separate data loggers can introduce synchronization issues and additional points of failure, reducing overall system efficiency.

You also might like these articles:

- LABA7 Unveils New Specs for Electromagnetic Shock Dyno

- HIL Testing and Electromagnetic Actuators in Suspension Testing

- EMA vs Other Shock Dynos of LABA7

- LABA7 Introduces Novel Power Supply System for Electromagnetic Shock Dyno

- Electromagnetic Linear Actuator vs Scotch-Yoke Shock Dyno: Which One To Choose?

- EMA Power Supply Unit Shortlisted for Innovation of the Year 2024