LABA7 shock dyno: unleash the performance

Take your workshop to the next level with the LABA7 shock dynamometer. A precise, user-friendly, and reliable tool designed by racers and mechanics to simplify suspension testing.

We developed a range of four shock dynos, so you can choose the best shock dyno for you.

Featherlight Shock Dyno

| Dyno speed | Up to 1 900 mm/s |

| Maximum force | 10 000 N load cell |

| Adjustable stroke | 25-50-75-100 mm |

| Motor | 3 HP-220V electric motor |

| Mechanism | Scotch Yoke for accurate linear motion |

| Temperature sensor | Contactless, from -70°C to +380°C |

| Free mounting length | 0 - 850 mm |

| Dimensions | 552.1 x 1547 x 781 mm |

| Weight | 170 kg |

The entry to the shock-testing world comes in the form of the Featherlight dyno. This compact machine is oriented towards the MTB market and those who want to start their dyno work at a very affordable price. Featherlight shock dyno can be customized for certain racing disciplines so you could put it in your van and take it to the track.

Best to test shocks of:![]()

![]()

![]()

![]()

![]()

![]()

![]()

Price: 8 000 EUR

Light Shock Dyno

| Dyno speed | Up to 2 500 mm/s |

| Maximum force | 10 000 N load cell |

| Adjustable stroke | 25-50-75-100-120-150mm |

| Motor | 4 HP-220V electric motor |

| Mechanism | Scotch Yoke for accurate linear motion |

| Temperature sensor | Contactless, from -70°C to +380°C |

| Free mounting length | 0 - 955 mm |

| Dimensions | 600 x 1810 x 958 mm |

| Weight | 300 kg |

A more affordable version that is a must-have device for building, rebuilding, or tuning shocks and forks. It is perfect for testing MTB, road motorcycles, and road car suspensions.

Best to test shocks of:![]()

![]()

![]()

![]()

![]()

![]()

![]()

Price: 11 000 EUR

Mid Shock Dyno

| Dyno speed | Up to 2 500 mm/s |

| Maximum force | 15 000 N load cell |

| Adjustable stroke | 25-50-75-100-120-150mm |

| Motor | 5.5 HP-380V electric motor |

| Mechanism | Scotch Yoke for accurate linear motion |

| Temperature sensor | Contactless, from -70°C to +380°C |

| Free mounting length | 0 - 955 mm |

| Dimensions | 616 x 2208 x 1106 mm |

| Weight | 500kg |

It is the most popular version of our shock dynamometers as it provides the best price-to-performance ratio. It is perfect for dirt track, motocross, and track car suspension servicing and turning.

Best to test shocks of:![]()

![]()

![]()

![]()

![]()

![]()

![]()

Price: 15 000 EUR

Heavy Shock Dyno

| Dyno speed | 8-3000 mm/s |

| Maximum force | 15 000N load cell |

| Adjustable stroke | 25-50-75-100-120-150 mm |

| Motor | 10 HP-380V electric motor |

| Mechanism | Scotch Yoke for accurate linear motion |

| Temperature sensor | Contactless, from -70°C to +380°C |

| Free mounting length | 0 - 955 mm |

| Dimensions | 616 x 2208 x 1106 mm |

| Weight | 550 kg |

This is the most powerful version of our shock dynamometers. It can service any shock and fork but is best suited for off-road cars, 4X4s, trucks, or advanced motocross suspension work.

Best to test shocks of:![]()

![]()

![]()

![]()

![]()

![]()

![]()

Price: 19 000 EUR

Looking for even more power and precision?

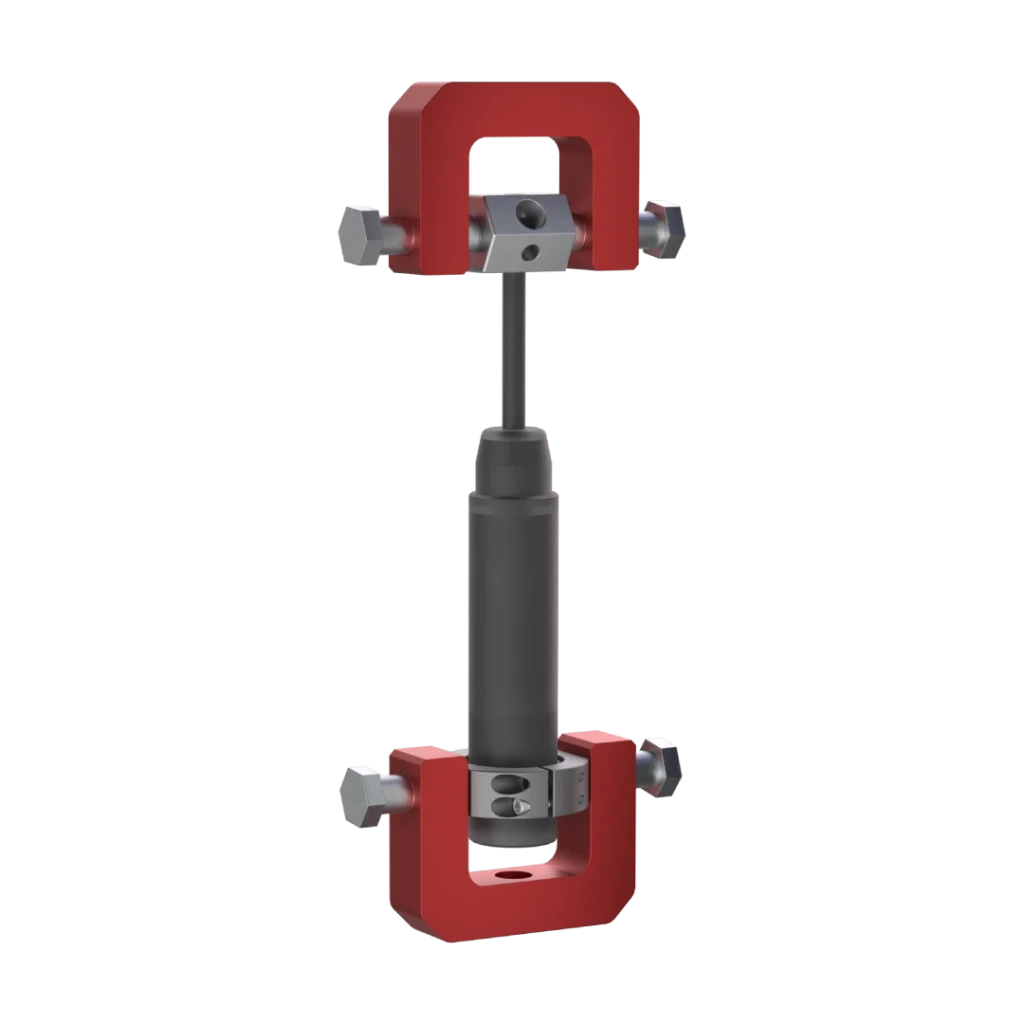

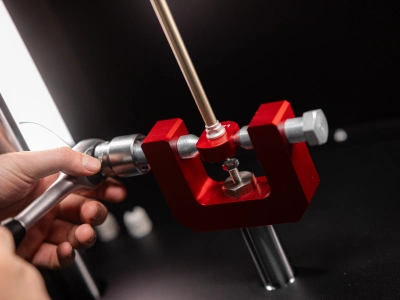

Expand your possibilities with shock dyno adapters

LABA7 shock dyno adapters create a seamless link, allowing for the most accurate and insightful tests of your shock absorbers. The result – enhanced performance, efficiency, and a deeper understanding of your equipment’s capabilities.

Focused on a flawless performance

LABA7 damper dynos are optimized for ultimate accuracy but at the same time, they are very easy to use and reliable.

We developed a range of four damper dynamometers so that you can choose the best shock dyno for you. Whether you are opening your first suspension workshop or are an experienced professional, we have the right machine for you.

Our suspension dynos are perfect for tuning and servicing bicycle, motorcycle, truck, or racing suspensions. If you can’t find what you need, we will develop a custom solution for you.

Advantages of LABA7 shock dynos

Accuracy

In the world of suspension, precision is key. Sometimes, a mere one-click adjustment can make the difference, ultimately determining the outcome of a race. That is why choosing the best shock dyno for your work means choosing the one that provides the most accurate data.

Our in-house data logger is capable of reading thousands of times per second.

We optimized our shock dynos to reduce electrical noise, which in turn minimizes the need for digital processing and filtration of the data. As a result, the data obtained and provided to you is extremely close to the original signal.

Additionally, all LABA7 shock dynos feature a Scotch-Yoke mechanism. This design allows us to provide you with uninterpreted and accurate data.

Reliability

The reliability of our equipment is greatly attributed to its simple yet sturdy architecture. Most of the components are overbuilt to last long.

To guarantee exceptional build quality, we assemble all LABA7 shock absorber dynos at our headquarters. Every unit undergoes rigorous testing and calibration before being shipped, ensuring that our customers receive flawless products.

Customer-driven perfection

At LABA7, we prioritize our customers and aim to maintain an ongoing relationship beyond the point of purchase. We welcome and value your feedback, which we use to continuously improve our machines. Once these features are tested and validated, we make them available to all our customers through regular updates.

Intuitive software

To ensure accuracy, simplicity, and reliability, we have developed software that matches the capabilities of our hardware. Our modern and intuitive software provides hassle-free operation with the click of a button. You can quickly access all the graphs and dyno data sheets, compare different tests, and print out the reports. Even more – track performance in real-time in force vs velocity and force vs displacement graphs.

Our goal is to ensure simplicity and clarity in all that we do, and we are proud to have achieved this according to feedback from our clients.

Main features of our shock dyno software:

- Easy-to-understand graphs and data

- Print-ready reports

- Runs on Windows OS

- Easy to use

- Simple calibration of the sensor

- Simple Wi-Fi setup

- Export to .csv

Customer assistance

Our commitment to our customers goes beyond the sale of our shock dynos. We deliver best-in-class support for our customers whenever they need our assistance.

The support for the customer starts as soon as our clients receive their shock dyno. Our professional team guides them through the setup process and shares the best practices to start using the equipment efficiently. Even later, when they have any questions, our team is ready to assist and resolve any questions immediately.

If you need a reference, just let us know. We have many satisfied customers who are eager to share their unique experiences with LABA7 and the exceptional support we provide.

Versatility

There are many types of different shock absorbers, forks, and cartridges in the market. To ensure that our shock dynos can handle all your suspension testing needs, we offer a wide range of adapters that fit various models.

Discover the full list of LABA7 shock dyno adapters at the bottom of the page.

Smart design

The industrial design of our equipment is a true work of art. It boasts a modern and sleek aesthetic that is not only visually appealing but also represents our commitment to quality, simplicity, and precision.

The sophisticated design of LABA7 shock dynos is sure to make a lasting impression on the visitors of your shop and enhance the overall look of any workspace.

Benefits of owning a shock dyno

Diagnose a faulty shock absorber or fork

A shock dyno can quickly diagnose issues with shock absorbers or forks within seconds. By examining the Force vs. Displacement graph, you can easily see what is happening with the damper during compression and rebound. Blocked oil passages, broken shims, cavitation due to a lack of gas pressure, and much more can all be quickly identified by analyzing the dyno graph.

Compare the performance

Navigate tuning and adjustment

Quality control and warranty

Performing quality control before releasing products to customers is a critical step in ensuring customer satisfaction. By testing the damper on the dyno before returning it to the customer, you can check your work and eliminate any possibility of errors. This not only reduces the chances of unsatisfied customers, but it also helps you prove that all work was done correctly on your end in case of any warranty claims caused by customer damage.

How does a suspension dyno work?

A shock dyno machine mimics the forces and speeds that your dampers undergo during real-life usage. By displaying this information in easy-to-read graphs, the dyno allows for detecting and resolving any issues with your shocks. In other words, LABA7 testing equipment helps you diagnose and fix problems of your shocks by displaying their performance data in a user-friendly manner.

The testing process involves repeatedly moving the fork or shock up and down at a speed of your choosing, enabling you to make precise diagnoses and corrections. You can damper test your shocks at different speeds and visualize the information through live graphs of force vs velocity and force vs displacement.