LABA7 Shock Dyno: Precision Testing for Maximum Performance

Take your workshop to the next level with the LABA7 shock dynamometer, a high-precision, user-friendly, and reliable shock dyno designed by racers and mechanics to simplify shock absorber and suspension testing. We have developed a range of 5 advanced LABA7 shock dynos, tailored to your specific suspension testing needs.

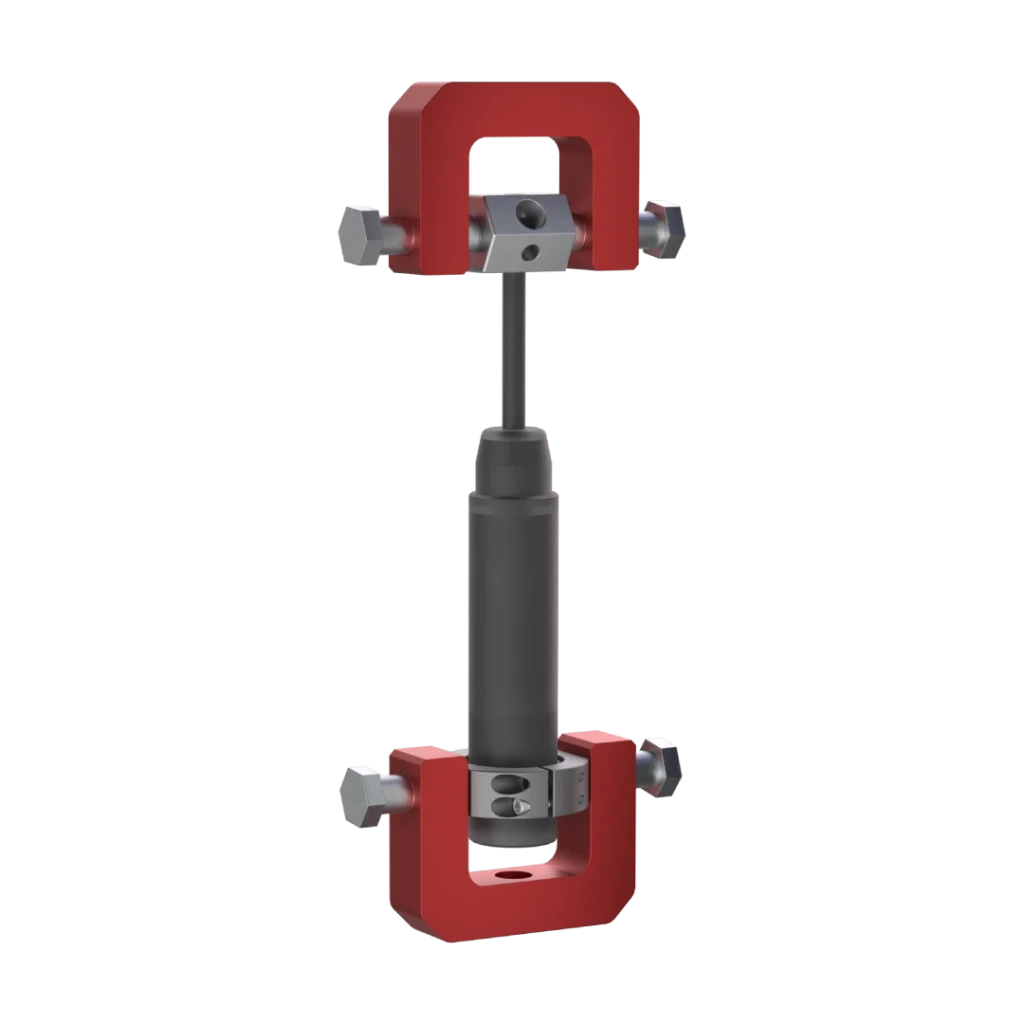

Scotch-Yoke Crank Shock Dynos

Featherlight

Light

Mid

Heavy

Super Heavy

*Smaller load cells are available upon request.

Looking for even more power and precision?

How Does a Suspension Dyno Work?

A suspension dyno accurately simulates the forces and speeds your shock absorbers and dampers experience during real-world riding or driving conditions. By replicating these movements, the dyno provides precise, repeatable tests that help you identify performance issues and optimize suspension settings.

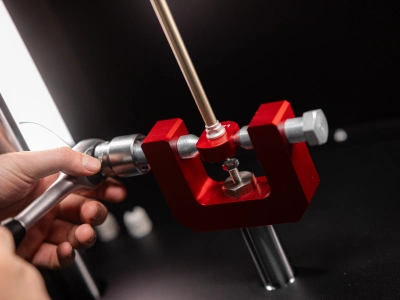

During testing, the dyno moves the fork or shock absorber up and down at user-selected speeds, closely mimicking actual suspension travel. This controlled motion allows you to diagnose problems such as blocked oil passages, worn components, or cavitation caused by gas pressure loss.

All test data is displayed in clear, real-time graphs including force versus velocity and force versus displacement, making it easy to analyze shock behavior during compression and rebound phases. With this insight, you can make informed adjustments to improve suspension performance, safety, and ride quality.

LABA7 shock dynos deliver this advanced testing capability through intuitive software and precise hardware, empowering mechanics and racers to tune shocks confidently and accurately.

Key Features of LABA7 Shock Dynos

Accuracy

In the world of suspension, precision is key. Sometimes, a mere one-click adjustment can make the difference, ultimately determining the outcome of a race. That is why choosing the best shock dyno for your work means selecting the one that provides the most accurate data.

Our in-house data logger is capable of reading thousands of times per second. We have optimized our shock dynos to minimize electrical noise, reducing the need for extensive digital processing and data filtration. As a result, the data obtained and provided to you is extremely close to the original signal.

Additionally, all LABA7 shock dynos also feature a Scotch-Yoke mechanism, allowing us to deliver uninterpreted and highly accurate data.

Reliability

The reliability of our equipment results from its simple yet robust design. Most components are built to exceed standard durability requirements, ensuring long-lasting performance.

To guarantee exceptional build quality, we assemble all LABA7 shock absorber dynos at our headquarters. Each unit undergoes rigorous testing and precise calibration before shipment, ensuring our customers receive perfect, ready-to-use products.

Customer-driven Perfection

At LABA7, we prioritize our customers and strive to build lasting relationships well beyond the initial purchase. We actively welcome and value your feedback and continuously use it to improve our shock dynamometers and suspension testing equipment.

Once new features are thoroughly tested and validated, we promptly roll them out to all customers via regular software and hardware updates. Our commitment to ongoing product enhancements ensures that LABA7 customers consistently receive the latest innovations and improvements, keeping our shock dynos state-of-the-art and ahead of the competition.

Intuitive Software

To ensure accuracy, simplicity, and reliability, we have developed powerful software fully integrated with our hardware. Our modern and intuitive software offers hassle-free operation with just a click of a button. You can quickly access all graphs and dyno data sheets, compare different tests, and print professional reports. Even more — monitor performance in real time using force vs velocity and force vs displacement graphs.

Our goal is to ensure simplicity and clarity in everything we do, and we are proud to have achieved this, according to consistent positive feedback from our clients.

Main features of our shock dyno software:

- Easy-to-understand graphs and data

- Print-ready professional reports

- Compatible with Windows OS

- User-friendly interface

- Simple sensor calibration

- Easy Wi-Fi setup

- Export to .csv format

Customer Assistance

Our commitment to customers goes beyond the sale of our shock dynos. We provide best-in-class, responsive support whenever you need it.

Support begins immediately upon delivery, with our professional team guiding you through setup and sharing best practices to ensure efficient use. If you have any questions later, our team will be ready to provide prompt assistance and resolve any issues.

Need references? We have many satisfied customers eager to share their unique experiences with LABA7 and the exceptional support we provide.

Versatility

The market offers many different types of shock absorbers, forks, and cartridges. We provide a complete range of adapters compatible with various models to ensure our shock dynos meet all your suspension testing needs.

Smart Design

The industrial design of our equipment is a true work of art. It features a modern, sleek aesthetic that is visually appealing and reflects our commitment to quality, simplicity, and precision.

The award-winning design of LABA7 shock dynos will make a lasting impression on your workshop visitors and improve the overall look of your workspace.

Expand Your Possibilities with Shock Dyno Adapters

LABA7 shock dyno adapters provide a seamless connection, providing the most accurate and insightful testing of your shock absorbers. This results in enhanced suspension performance, improved testing efficiency, and a deeper understanding of your suspension system’s capabilities.

Benefits of Owning a Shock Dyno

Diagnose a Faulty Shock Absorber or Fork

A shock dyno can quickly identify and diagnose common issues with shock absorbers or forks within seconds. By examining the force vs displacement graph, you can easily understand what is happening with the damper during compression and rebound. Problems such as blocked oil passages, broken shims, cavitation caused by low gas pressure, and more can all be rapidly detected through detailed dyno graph analysis.

Compare the Performance

With our shock dyno’s advanced comparison feature, you can effortlessly visualize and analyze changes made to your shock absorber or fork. Whether comparing left versus right, front versus back dampers, or different damper settings, our dyno clearly shows the before-and-after effects of your tuning or servicing. This feature is also highly effective for demonstrating performance improvements to customers.

Navigate Tuning and Adjustment

Successful suspension tuning requires accurate data and a thorough understanding of shock absorber behavior. By analyzing graph curves alongside rider feedback, you can make data-driven, precise adjustments to fine-tune suspension performance according to the rider’s needs. The shock dynamometer excels here by providing clear visual feedback on how your adjustments affect damper behavior and translate to improved track or road performance.

Quality Control and Warranty

Performing quality control testing on the dyno before returning products to customers is a vital step in guaranteeing customer satisfaction. By thoroughly testing the damper, you can verify your work and eliminate potential errors, reducing the risk of dissatisfied customers. Additionally, this testing provides solid evidence that all work was performed correctly, which can be invaluable in warranty claim situations related to customer damage.

Want More Control and Precision?

If you’re ready to take shock testing further, the EMA Shock Dyno (electromagnetic actuators) delivers superior precision, control, and better performance. Using an electromagnetic linear actuator, it simulates real-world conditions with programmable motion profiles, including non-sinusoidal waveforms that a Scotch-Yoke dyno can’t replicate.

The EMA Shock Dyno also covers a wider speed and displacement range and typically requires less maintenance thanks to fewer mechanical wear points. While it comes at a higher cost and complexity, it’s the go-to choice for professional setups demanding maximum accuracy and flexibility.

Frequently Asked Questions About Shock Dyno

What is a shock dyno and why do I need one?

A shock dyno (dynamometer) measures the performance characteristics of suspension dampers (shocks). It helps you analyze compression and rebound forces, identify inconsistencies, and optimize suspension setups for racing or performance applications.

Is the dyno software included and what does it do?

Yes, the dyno includes intuitive software that records, graphs, and analyzes force vs. velocity and displacement data. It allows you to compare multiple runs, export results, and fine-tune your suspension setup.

What types of shocks can this dyno test?

Our shock dyno is compatible with a wide range of shocks, including mono-tube, twin-tube, coilover, motorcycle, off-road, and racing dampers. Specific adapter kits may be required for certain models.

How accurate are the results?

Our shock dynamometers are engineered with high-precision sensors and calibrated to ensure industry-leading accuracy. This ensures consistent, repeatable measurements for professional and amateur use alike.

What are the setup and maintenance requirements?

The dyno arrives with a detailed setup guide and requires only a standard power outlet and a stable surface. Maintenance is minimal, primarily keeping the sensors and actuator clean and calibrated annually for best results.