Since its inception in 2020, LABA7 has been transforming the world of suspension testing with its groundbreaking technology. By blending precision engineering and innovative design, the company has quickly become a leader in delivering powerful hardware and software solutions that redefine suspension tuning.

Revolutionizing Suspension Testing with the EMA

One of LABA7’s biggest breakthroughs is the Electromagnetic Actuated (EMA) Damper Test System.

“Our EMA machine can simulate real-world track conditions in a controlled environment. That means faster, more precise suspension tuning without endless on-track testing,” said Andreas Liškus, CEO of LABA7.

Unlike traditional hydraulic dynos, the EMA uses electromagnetic force, providing faster, more accurate testing of suspension components. With a velocity of up to 7 m/s and a 40 kN force capacity, the EMA delivers unparalleled precision, simulating real-world track conditions with advanced waveform control.

For motorsport teams and suspension tuners, precision matters—especially when every millisecond counts. LABA7’s EMA system helps teams make data-driven decisions that lead to better, faster performance on the track.

Advanced Technology Behind the EMA

LABA7’s Electromagnetic Actuated (EMA) damper testing system stands out due to its fully in-house development process. Unlike competitors who use off-the-shelf controllers and power regulators, LABA7 designed and built custom electronics, power distribution units, and control algorithms from the ground up.

“We didn’t take existing components and piece them together,” said CEO Andreas Liškus. “Everything, from the power supply units to the motion control software, was developed in-house to ensure maximum precision and flexibility.”

A key technological advantage of the EMA is its real-time waveform control, allowing engineers to test shock absorbers in ways previously impossible with hydraulic dynos. EMA supports these waveforms: Sine, Triangle, Square, Pulse, Pink noise, Sweep, Chirp, and Direct track data import.

LABA7 developed proprietary power regulation technology that enables high-power testing without requiring high-power mains installations, solving a common problem in workshops with limited electrical capacity.

“We implemented special power control systems that allow our machines to run efficiently without huge power requirements,” Liškus explained. “That means you can achieve extremely high test forces and speeds even in a standard workshop environment.”

Smarter Data, Smarter Decisions

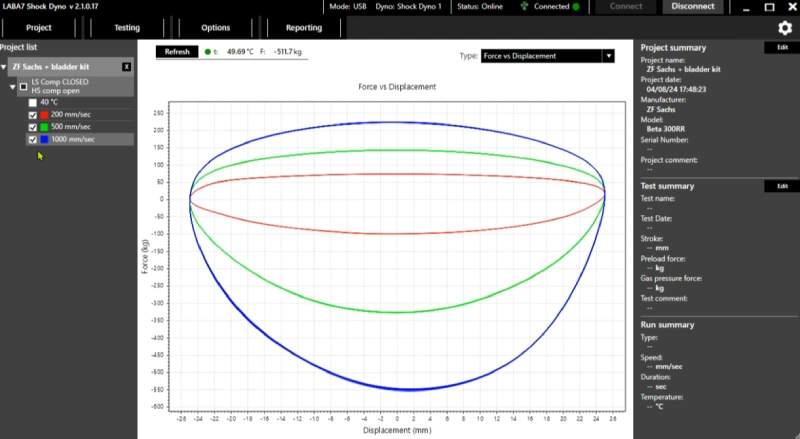

Data accuracy is at the core of LABA7’s philosophy. Their systems collect high-resolution test data, ensuring that even the smallest anomalies in damper performance are detected.

“We don’t filter or manipulate test results. What you measure is exactly what you get,” said Liškus. “That level of transparency is critical for engineers fine-tuning performance.”

LABA7 also integrates telemetry data, allowing teams to import real track conditions and replicate them in the lab. This feature eliminates the need for repeated track testing, saving time and reducing costs.

Expanding the Limits of Suspension Engineering

LABA7’s product lineup has grown beyond just shock testing. Their spring rate measurement machines, vacuum bleeder pumps, and wireless race car scales have all gained traction in workshops and race teams worldwide.

“Our customers range from Formula 1 teams to independent suspension tuners. Whether it’s a world-class manufacturer or a local performance shop, we provide tools that make their work easier and more precise,” Liškus explained.

LABA7 is also developing a climatic chamber add-on for their EMA machine. This will allow engineers to test suspension performance in extreme temperatures and humidity conditions, crucial for endurance racing and off-road applications.

Installation and Training: Getting Users Up to Speed Quickly

LABA7 designs its products to be plug-and-play for most users. Standard machines like shock dynos, spring testers, and vacuum bleeders require minimal setup and can be used immediately after delivery. For customers who purchase these products, LABA7 offers live online training sessions, ensuring that even those on the other side of the world receive expert guidance.

However, for advanced systems like the EMA, LABA7 provides on-site installation and training to ensure customers get the most out of their investment.

“With the EMA, we travel to the customer’s location, install the machine, and conduct in-depth training,” Liškus said. “We don’t just show you how to press buttons—we make sure you understand how to interpret the data and use it to optimize suspension performance.”

The company’s 24/7 customer support team is also available to troubleshoot any issues, whether it’s a technical question or a request for software updates.

Real Feedback from the Industry

During the webinar, professionals from the OEM, motorsport, and suspension tuning industries had the opportunity to ask questions and share their experiences with LABA7’s technology. Here are some highlights:

Q: Can the EMA simulate rider weight and terrain to evaluate suspension settings?

A: “Yes, our EMA machine can simulate real-world riding conditions by using track data. You can load actual telemetry and replicate those forces in a controlled environment,” Liškus explained.

Q: Are there plans to develop telemetry sensors to work with the EMA?

A: “We’ve researched this extensively. The market is competitive, but if we enter, we will do it properly,” Liškus assured.

Q: What is the power and speed capability of the EMA?

A: “It can reach up to 7 meters per second and deliver forces up to 40 kN, covering everything from lightweight motorcycle shocks to high-force automotive dampers,” he detailed.

Comment from Simon Rogers, Race Shocks UK:

“Our LABA7 spring dyno is an underrated tool. We use it daily, and it has become one of the best sales tools for our shop. Customers see the actual data and immediately trust the results.”

Comment from a workshop owner:

“We’ve been using LABA7’s shock dyno since 2020. It’s been rock solid and incredibly valuable for our daily work. Looking forward to seeing what’s next!”

Customer Success Stories: Solving Real-World Suspension Problems

LABA7’s shock dynos and testing equipment have helped professionals identify and solve suspension issues that would otherwise go unnoticed.

A. Liškus shared one memorable case that involved a rally team struggling to find the right setup. The test driver insisted that the dampers were “too stiff,” but when the team put the shocks on LABA7’s dyno, they discovered the opposite—they were actually under-damped by a factor of six.

“This was a classic case where human perception didn’t match the data,” Liškus said. “Without precise measurements, they would have continued making adjustments in the wrong direction.”

Another customer had a recurring issue with a leaking shock absorber. Despite multiple rebuilds, the problem persisted. Determined to find the root cause, the technician decided to run the shock on LABA7’s dyno at high temperatures. After heating the damper to nearly 100°C, they finally saw what had been hidden—the shock body had a microscopic crack that only expanded under heat and pressure.

“Without a shock dyno, this issue would have remained a mystery,” Liškus noted. “This kind of testing capability prevents expensive warranty claims and keeps customers happy.”

Compatibility with Roehrig Data Files

One of the biggest concerns for workshops investing in new testing equipment is data continuity—especially for those who have years of test results stored in legacy formats. LABA7 addressed this issue by making its software compatible with old Roehrig shock dyno files, a feature that was highly praised during the webinar.

“We know that Roehrig machines was industry standards for decades,” Liškus said. “That’s why we made sure our software could open and overlay their historical test data seamlessly.”

This means that engineers and suspension tuners who switch to LABA7 can directly compare their old data with new tests, ensuring they maintain their development records without having to start from scratch.

“Our goal is to make the transition as smooth as possible,” Liškus added. “We don’t want anyone to feel like they’re losing valuable insights just because they’re upgrading to better technology.”

The Future of LABA7

LABA7 focuses not only on the present—it’s driving the future of suspension and automotive testing. With plans to expand into power measurement tools and other automotive sectors, LABA7 continues to break new ground in engineering solutions that empower professionals worldwide.

“We’re constantly pushing the boundaries,” said Liškus. “Our goal is to develop tools that help engineers, mechanics, and manufacturers work smarter and faster. Every product we create is designed to make a real impact.”

With customers in over 40 countries, LABA7 is growing fast. Their reputation for innovation, accuracy, and reliability has made them a go-to choice for top-tier motorsport and automotive professionals.

Ready to elevate your suspension testing? Learn more about LABA7’s groundbreaking technology and how it can transform your work by visiting our website or reaching out for a consultation.