Some brands claim that using a shock dyno to measure the spring rate of a spring is an appropriate way of testing. Just because you can do something doesn’t mean you should. Let us explain why it’s not safe, accurate, or even healthy for your equipment.

If you don’t know what is a spring rate and why it matters, check the post in the link.

You also can watch the video:

Safety

First, as the name suggests a shock dyno is not designed for testing spring safety. Most shock dynos don’t have protective covers, proper holders, or other safety mechanisms crucial for handling high-tension springs.

When springs are compressed, they store huge amounts of kinetic energy. Without the mentioned safeguards, there’s a serious risk of injury if something goes wrong.

Spring preload

Secondly, on shock dynos, there’s no option for preloading the spring. This is a big issue because it makes it hard to test springs under the same conditions, which can be challenging when you are testing several springs.

Springs come in many shapes and sizes. A spring rate tester is designed to measure them all. When you use a damper dyno for this job, remember…

Stroke length

Then there’s the matter of stroke length and spring length. Shock dynos are designed to handle specific strokes, which are shorter than what’s needed for most springs.

This limitation means you can only test linear shock springs, so never mind testing fork springs and progressive shock springs.

Accuracy

And let’s not forget about accuracy. Shock dynos aren’t as precise for this type of testing. There are multiple reasons for this:

- They rely on human input and calculations, which are prone to error.

- Its compression speed is not linear, but accelerating/decelerating (sinusoidal).

- Slowly compressing the spring on a damper dyno motor will introduce the Cogging effect which needs to be filtered and can introduce additional errors.

- Unlike a dedicated spring dyno that compresses springs in a slow linear motion and automatically calculates an average spring rate, shock dynos force you to rely on maximum load values. This can lead to variations that affect the true spring rate performance.

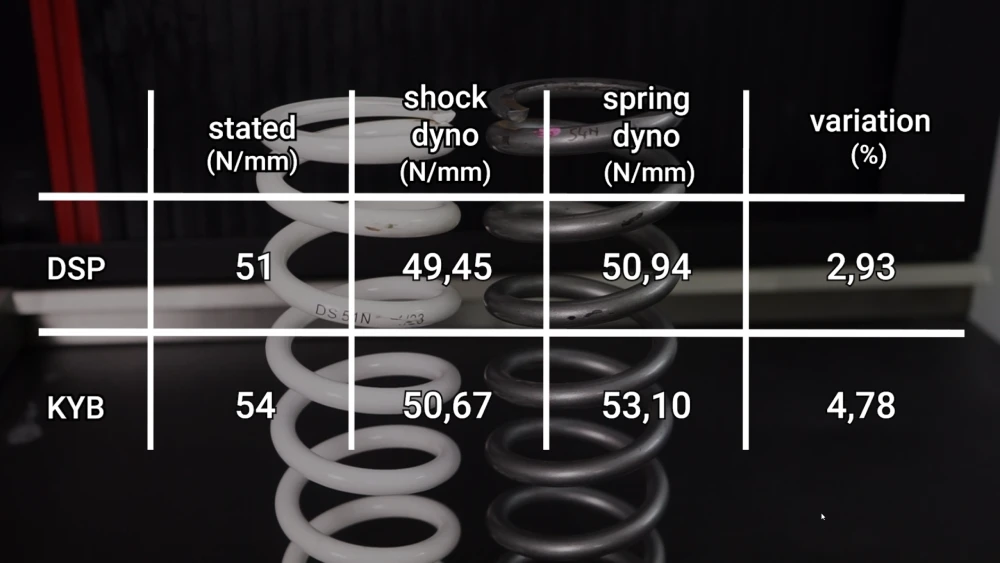

To prove our point we experimented. Using the methodology, suggested by another brand, we tested two springs—one DSP and another KYB—using both a shock dyno and a spring dyno.

The results were clear: the shock dyno’s variation was beyond acceptable limits. With up to a 4.78% deviation, it’s simply not accurate enough. Taking into account the risks mentioned, we highly discourage doing so.

For critical components like springs, even a small deviation can have a huge impact on your vehicle’s safety and performance.

So, can you measure a spring rate on a shock dyno?

So, can you measure the spring rate with a shock dyno? Yes. Should you? NO!

If you’re serious about getting the right spring rate, stick to a dedicated spring dyno. It’s safer, more accurate, and better for your equipment.

Make decisions on accurate data!