Shock absorbers play a critical role in the performance and comfort of vehicles, from dirt bikes to race cars. Understanding how their adjustable features, known as clickers, influence damping is essential for tuning them effectively. This blog explores the mechanics of clickers in shock absorbers and how LABA7’s state-of-the-art shock dyno enables precise testing and insights for different dampers.

Table of Contents

- What Are Clickers in Shock Absorbers?

- Types of Adjustments in Shock Absorbers

- Using LABA7’s Shock Dyno for Analysis

- Key Insights from Shock Dyno Testing

- Building a Comprehensive Test Library

What Are Clickers in Shock Absorbers?

Clickers are adjusters on shock absorbers that allow you to fine-tune the damping characteristics. They control the flow of oil within the shock, altering the resistance and behavior of the suspension. These adjustments are crucial for optimizing comfort, handling, and performance in various conditions.

Types of Adjustments in Shock Absorbers

Low-Speed Compression Adjuster

The low-speed compression adjuster influences the initial part of the compression stroke. It is responsible for the suspension’s response to slow, subtle movements. Key effects include:

- Comfort vs. Harshness: A steeper damping curve at the start of the shock dyno graph indicates more harshness.

- Bottoming Resistance: Increased damping throughout the stroke helps prevent the suspension from fully compressing.

High-Speed Compression Adjuster

As the name suggests, this adjuster affects the suspension’s behavior during rapid compression movements, such as hitting a pothole or landing a jump. Characteristics include:

- High-Speed Impacts: Enhanced resistance to sharp, fast inputs.

- Sensitivity: In the tested shock, it interacts with the low-speed adjuster for combined effects.

Rebound Adjuster

The rebound adjuster controls the extension of the shock after compression. It affects the entire volume of oil moving through the shock and has a significant impact on:

- Damping Amplitude: Rebound adjustments cause noticeable changes in damping behavior.

- Interaction with Compression: Changes to rebound settings also influence compression characteristics.

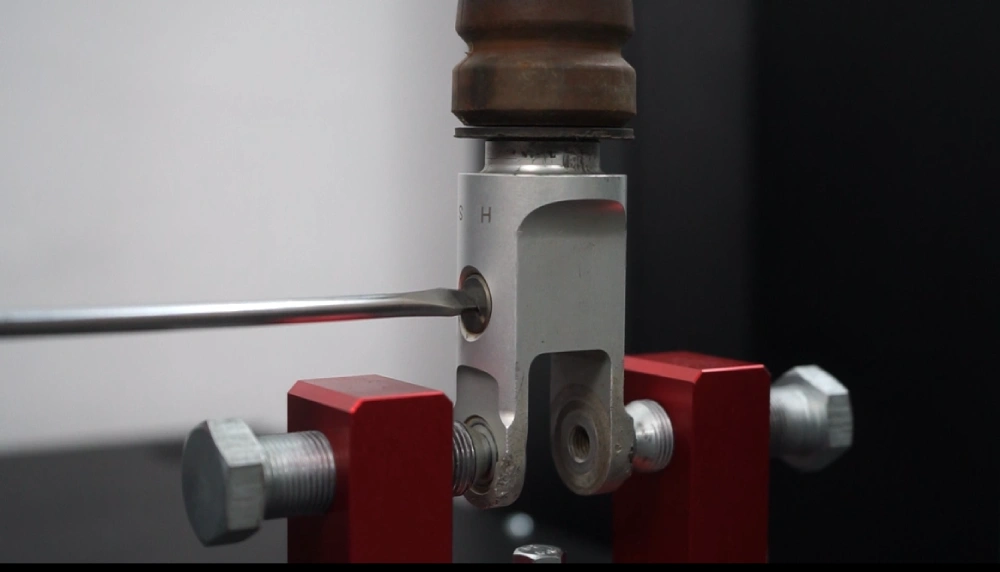

Using LABA7’s Shock Dyno for Analysis

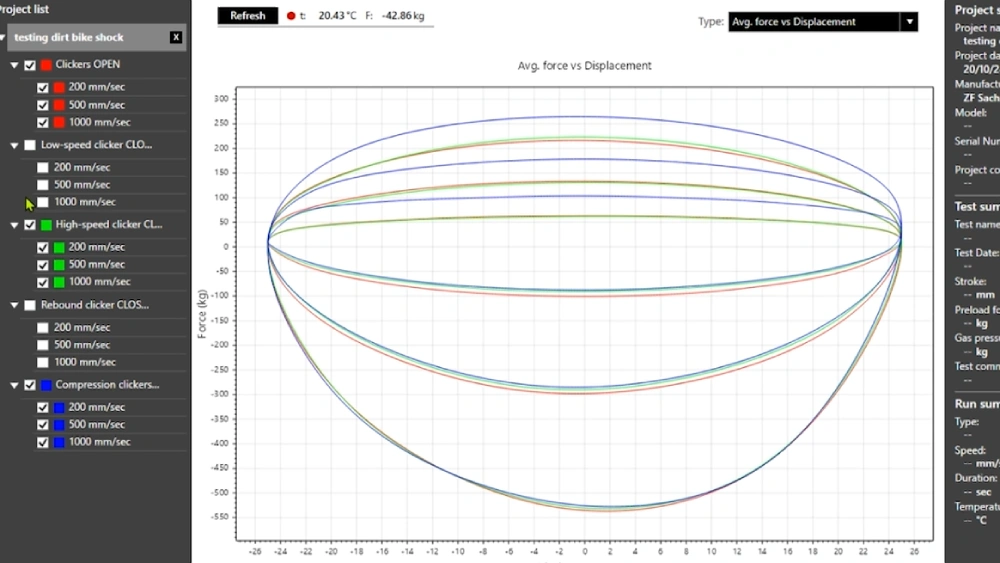

LABA7’s shock dyno provides a detailed view of shock performance by simulating real-world conditions and recording precise data. In a typical test, a shock absorber is cycled at various speeds, such as:

- 200 mm/s: Simulating low-speed compression.

- 500 mm/s: Representing medium-speed compression.

- 1000 mm/s: Mimicking high-speed compression.

The shock is tested with different clicker settings, including:

- All clickers fully open (control test).

- Low-speed compression closed.

- High-speed compression closed.

- Both compression adjusters closed.

- Rebound adjuster closed.

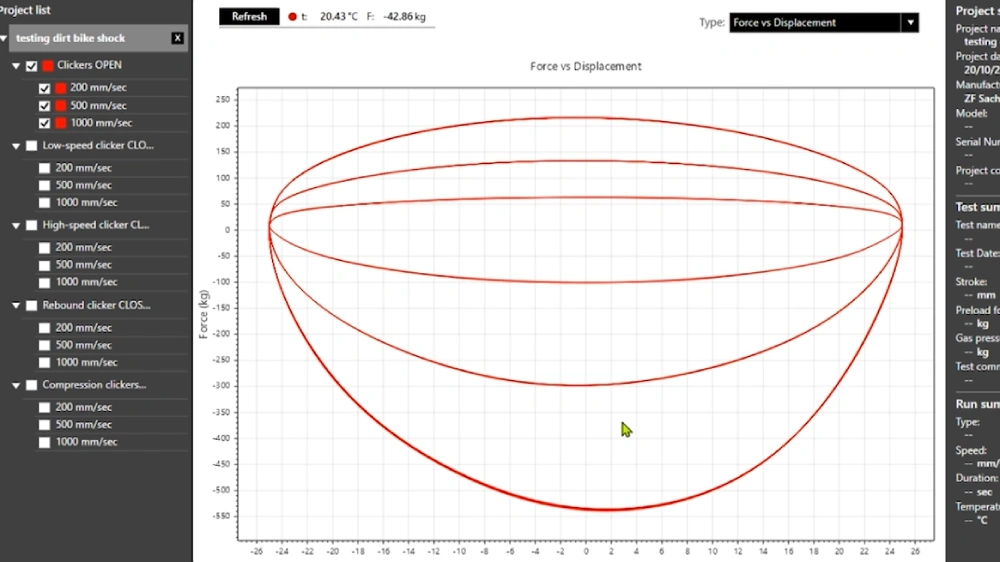

These tests generate graphs that illustrate the damping force over the displacement of the shock.

Key Insights from Shock Dyno Testing

Analyzing Compression Damping

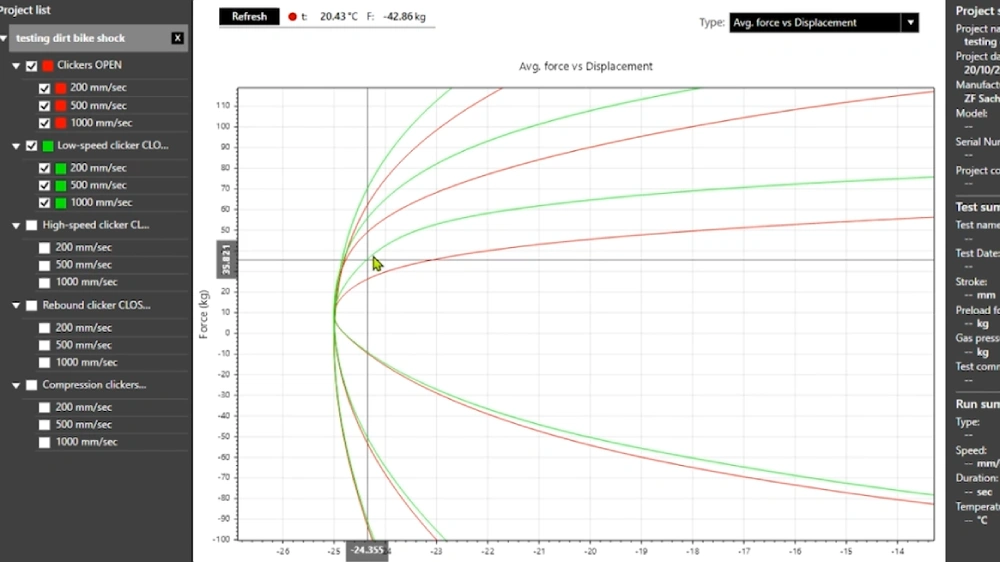

By comparing test results, LABA7’s shock dyno reveals how each adjuster impacts compression damping:

- Low-Speed Adjustments: Increased damping early in the stroke indicates greater resistance to subtle movements.

- High-Speed Adjustments: Changes are more prominent at high-speed compression, showing how the shock handles rapid impacts.

- Combined Adjustments: Testing both adjusters closed demonstrates their interplay and cumulative effects.

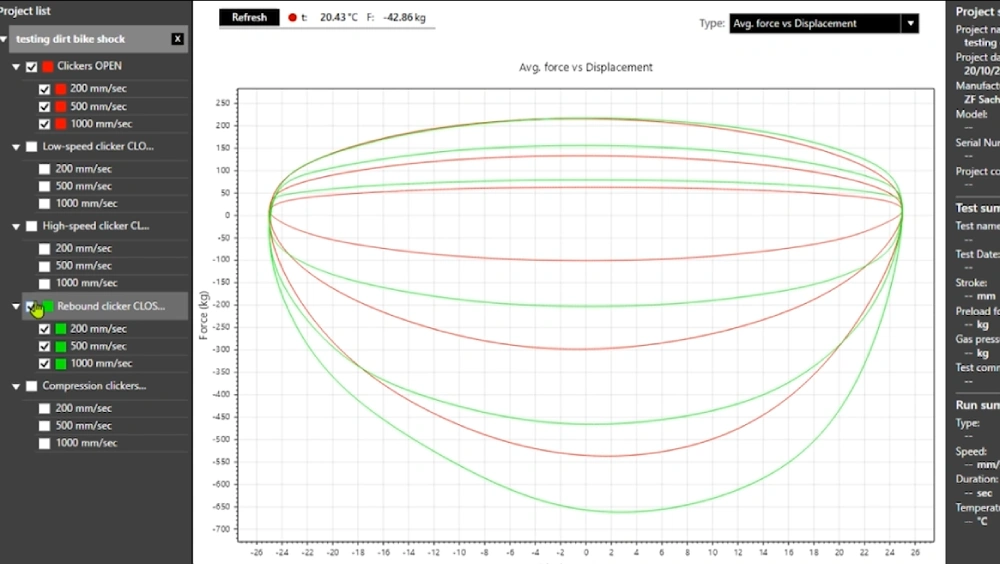

Understanding Rebound Damping

Rebound damping tests highlight significant changes due to the adjuster’s influence on the oil volume moving through the shock during rebound and compression as well. Key takeaways include:

- Rebound adjustments produce a wide range of damping responses.

- Changes to rebound settings can affect compression characteristics, emphasizing the importance of testing configurations holistically.

Building a Comprehensive Test Library

LABA7’s intuitive shock dyno software allows operators to save and compare test results, building a valuable resource for:

- Identify erratic behaviors or inconsistencies in shocks.

- Use historical data to inform tuning decisions.

- Leverage accumulated insights for challenging cases.

With LABA7’s shock dyno, understanding and optimizing shock absorber performance has never been easier. By mastering the interplay of clickers and analyzing test results, you can ensure that every ride—whether on the road or the track—delivers peak performance and comfort.