Shock absorbers are the unsung heroes of performance and daily driving. They absorb the unpleasant effects of bumpy roads and unavoidable holes. Whether you are driving a car, motorcycle, or a bike they are crucial for safety, stability, and comfort during your journey.

Below you will find a comprehensive guide to shock absorbers, different types, and answers to frequent questions we receive about them.

- What is a shock absorber?

- What do shock absorbers do?

- How do shock absorbers work?

- Types of shock absorbers

- How long do shock absorbers last?

- What are the symptoms of bad shock absorbers?

- How do you test a shock absorber?

- Is it OK to repair shock absorbers?

What is a shock absorber?

A shock absorber is part of a car, bicycle, or motorcycle suspension. It also can be called a shock, fork, or damper. Whatever the name, its purpose is to reduce shocks and vibrations caused by uneven roads thus improving the handling and comfort of a vehicle.

Without dampers, drivers would be more likely to lose control of the vehicle, especially when driving at high speeds or on rough roads.

There are a few types of shock absorbers. They will be covered in detail later on in this article.

For introductory purposes, we will briefly mention that there are gas and oil (also called pneumatic and hydraulic) shocks. Most of the absorbers that use oil are made in mono-tube and twin-tube designs.

What do shock absorbers do?

Shock absorbers play a key role in maintaining tire contact with the road. It is vital for safe and efficient driving. Below you will find a brief overview of the function of dampers. If you would like to go deeper, visit our article about the purpose of a damper on a car.

That being said, one must keep in mind that different shock absorbers are designed for various purposes.

On a regular car shock absorbers are optimized for comfort. Generally, they are soft and designed to absorb shocks from road bumps and potholes.

Race car shock absorbers, on the other hand, are designed for handling and speed. They are much stiffer and provide more “feel” for the driver during high-speed driving and cornering.

Often racing shock absorbers are adjustable, allowing the driver to fine-tune the damping force to suit specific driving conditions and preferences. Typically they are constructed of lightweight materials and may have additional features. For example, remote reservoirs increase cooling and reduce fade during prolonged use.

Off-road shock absorbers are designed to withstand the extreme conditions and rough terrain encountered during off-road driving. Off-road car shock absorbers may also be adjustable, allowing the driver to adjust the damping force for different types of terrain. They also may have protective features such as reinforced housings and dust boots.

How do shock absorbers work?

In scientific terms, shock absorbers transform kinetic energy into heat and then disperse it into the atmosphere.

To put it in more simple terms, imagine a vehicle that encounters a bump on the road. When it hits the bump the shock is compressed, and then it is immediately stretched out to its normal state.

On the inside of a shock absorber, there is a piston. During this motion, the piston moves up and down, when the shock is compressed and stretched out.

While it was moving the hydraulic fluid that is also inside the shock was forced through many tiny holes in the piston. As the fluid cannot flow freely but has to squeeze these tiny holes, resistance is created. And that is the effect of shock absorption.

As in the previous example there was only one bump on the road, the amount of resistance was minimal, and very little heat was generated. But when a vehicle drives through many bumps on the road, the piston moves up and down many times very fast. Then the shock absorber generates much more heat that it “gives away” to the atmosphere.

If a shock absorber generates more heat than it can “give away”, it may result in overheating. In such a case, the driver will experience either bouncing, harsh rides, or even reduced braking performance.

Types of shock absorbers

There are two main shock absorber types in the market:

- Mono-tube

- Twin-tube

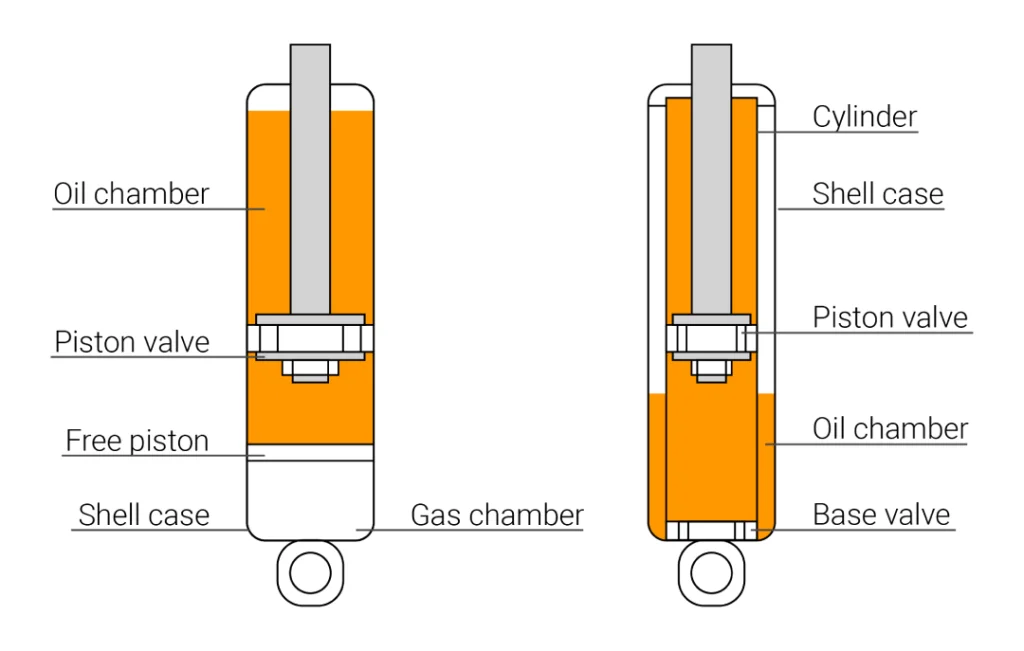

The main difference between mono-tube and twin-tube systems, as their names imply, is the number of tubes used for the shock absorber.

- Mono-tube. The shell case itself works as a cylinder and oil, gas, piston valve, and other parts are set inside that single tube. Mono-tube uses a free piston that completely separates the oil chamber from the gas chamber.

- Twin-tube. There is a cylinder set inside the shell case and the piston valve moves up and down within the inner cylinder. Nothing separates the oil and gas chambers within the shell case.

Mono-tube shocks: Pros & Cons

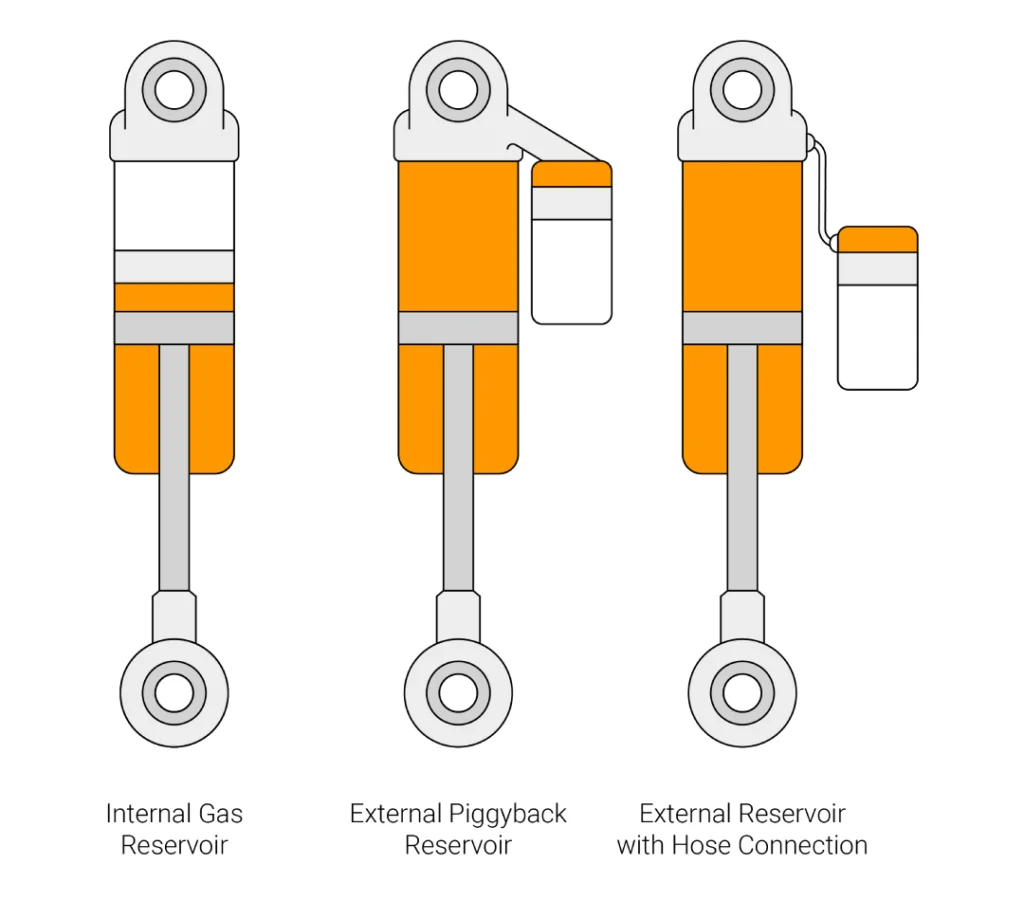

Different types of mono-tube shock absorbers:

- Internal gas reservoir

- External gas reservoir (piggyback)

- External gas reservoir with hose

Pros of Mono-Tube

- With increasing temperature, oil can dissipate heat more efficiently with less effort.

- The installation angles of mono-tube shock absorbers have zero restrictions.

- They are also less susceptible to cavitation, and their larger oil capacity and better heat dissipation enable stable and continuous damping.

- Since oil and gas are completely separated, the air is unable to penetrate the system.

- This design allows for 100% efficiency across all temperatures.

- In mono-tube systems, the piston valve is typically larger and wider, which allows for a greater area of pressure. Consequently, the shock absorber can produce even subtle damping forces with precision.

Cons of Mono-Tube

- A stiffer ride is expected because an injection of high-pressured gas is required in the structural design.

- These high-pressure gasses can also lead to a higher amount of stress on seals which can cause more friction.

- These shock absorbers are typically more expensive to manufacture.

- When the shell case experiences external damage or force, the inner cylinder is directly affected.

- Since the oil and gas chambers are positioned next to each other, it is increasingly difficult to maintain sufficient stroke.

Twin-tube shock: Pros & Cons

Pros of Twin-Tube

- External damage to the shell case has less impact on the shock absorber.

- The twin-tube design provides a superior manufacturing process which keeps the cost of production low.

- A base valve helps to keep gas pressure low, leading to a more comfortable ride.

- Low gas pressure reduces stress on seals and also keeps friction to a minimum.

- Thanks to the separation of the oil and gas chambers, sufficient stroke is achieved with less effort.

Cons of Twin-Tube

- The design of this shock absorber can be challenging during installation.

- As there is no separation between the oil and gas chambers, it can lead to cavitation and a consequent performance loss of up to 35%.

- The size of a piston is greatly decreased compared to the mono-tube design.

- Oil capacity is reduced in comparison to the mono-tube.

- Due to the low pressure, these shock absorbers are generally very soft.

- Smaller pistons may be more susceptible to heat and have limited damping capabilities.

- One-directional mounting.

Exotic types of shock absorbers

Ohlins TTX

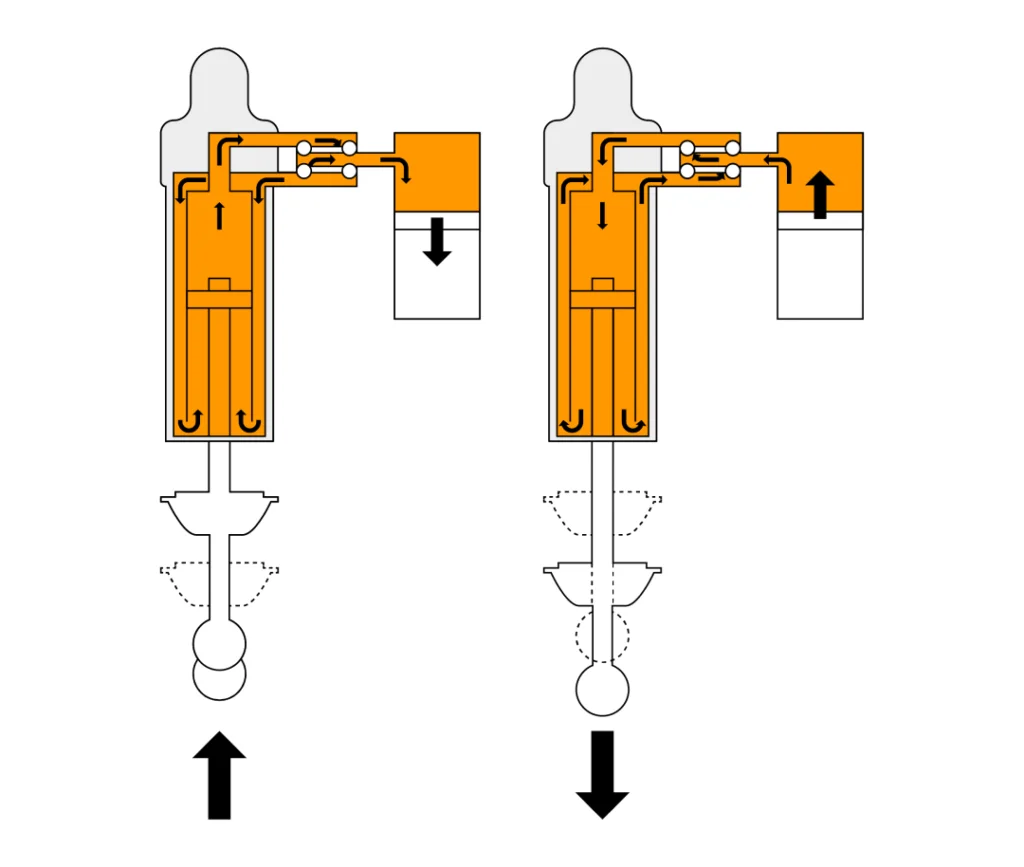

The Twin Tube X-over (TTX) shock absorber works a bit differently than the monotube shocks. The name comes from the way the fluid flows over the valves. Instead of flowing through the piston with ports and shims, the TTX usually has a solid piston.

When the shock is compressed, the fluid is pushed out through the top of the inner cylinder, through the compression adjuster valve, through the rebound check valve, through the outer cylinder, and finally back into the underside of the piston. As the shock is compressed, the same volume of fluid needs to be pushed out, which moves out to the reservoir.

When the shock rebounds, the fluid passes out of the inner cylinder, up the outer tube, through the rebound adjuster valve, then the compression check valve (crossing over the compression path hence TTX), and finally in the upper side of the piston. The fluid that needs to be replaced as the shock rebounds returns back from the reservoir.

Through shaft

Some shocks, like the Ohlins TTX40 and 46, Trek RE:aktiv, and others, have a rod that goes through the piston and out the other end. This makes the shock a lot less sensitive to side loading as the shaft is supported by bushes at opposing ends of the body. Also, as you don’t have any displacement change, as the damper goes into compression stroke there is no gas force to push against, making the damping more sensitive.

Nivomat

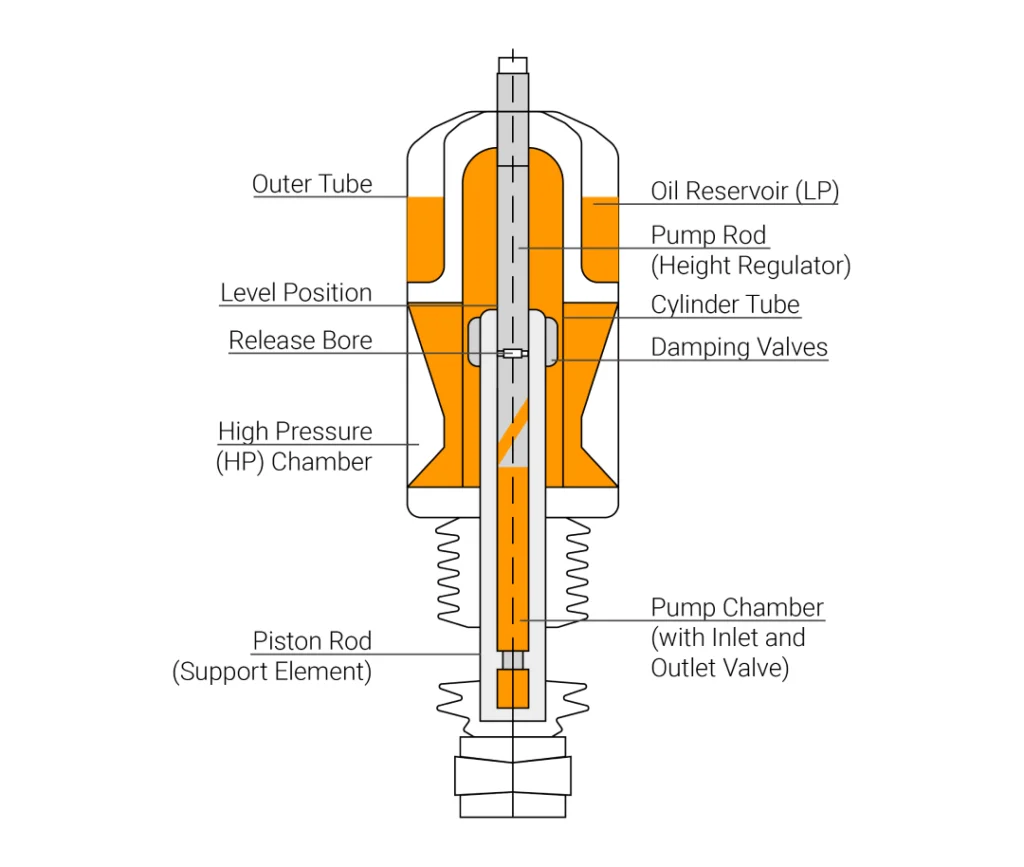

Nivomats are self-leveling (no spring needed) monotube shock absorbers designed by Sachs. They utilize the movement of the vehicle between the chassis and the body to create mechanical energy. They are typically mounted in the rear of the vehicle and are self-contained meaning they have no air compressors or air lines.

The way they work is as the load increases (such as with cargo and passengers) the pressure increases in the shock displacing fluid from its internal reservoir to its valving system increasing the spring rate essentially preventing the vehicle from “squatting”. It has a pump mechanism and oil reservoir that increases the pressure to its accumulator, therefore, lifting or leveling the vehicle. It also increases the damping force without sacrificing the ride quality.

How long do shock absorbers last?

Just like many questions in life, the answer is… it depends.

To begin with, are we talking about shocks of bicycles, motorcycles, daily cars, race cars, heavy-duty off-roaders, or trucks? What are the conditions of the road? What is the driving style? Are they being used in extreme conditions where temperatures are very high or very low? Is it a budget or premium shock absorber? Was it properly maintained? What are the levels of tolerances of the manufacturer?

To end with, what do you consider to be the “life”? Is it the timeframe between servicing or between purchases of a new set of shocks?

Having in mind all these variables, it is easy to understand that there is no definitive answer, and in the end, it… depends.

On the other hand, from our own experience and estimated VERY roughly, the service life of shock absorbers is as follows:

- Shock absorbers of a car should last for 80,000-160,000 km or 5-10 years.

- Shock absorbers for a race car should be serviced (re-built) every 30 hours of practice or racing.

- Shock for a motorcycle that is ridden on streets and public roads should last for 10,000-40,000 km or 2-5 years

- The shocks and forks of a racing motorcycle should be serviced after every race or after 10-15 hours of riding.

- Shocks and forks of bicycles should be serviced every 50-200 hours of riding.

What are the symptoms of bad shock absorbers?

When shock absorbers start to fail, there are certain indications. They depend on the severity and the nature of the problem. Here are some common signs to look out for:

- Poor ride quality: If the shock absorbers are worn out, damaged, or malfunctioning, the ride quality will be poor, and the vehicle may bounce excessively over bumps or rough roads.

- Excessive body roll: When turning corners or making sudden maneuvers, the vehicle may lean excessively.

- Nose dive or rear end squat: If the shock absorbers are not functioning properly, the front of the vehicle may dip forward when braking or the rear end may squat down when accelerating.

- Uneven tire wear: Worn or damaged shock absorbers can cause uneven tire wear, which may be noticeable as bald spots.

- Leaking fluid: If you notice oil or fluid leaking from the shock absorbers, it is a clear sign that the seals are worn out or damaged.

- Excessive noise: When driving over bumps worn or damaged shock absorbers will produce noise. For example, they will rattle, clunk, or bang.

- Reduced braking performance: They can affect the vehicle’s ability to stop quickly and safely, as the wheels may lose contact with the road surface more frequently due to increased bouncing.

If you notice any of these symptoms, it’s important to have the shock absorbers inspected by a professional mechanic and repaired or replaced. Driving with worn or damaged shock absorbers can be dangerous, as it can affect the vehicle’s stability, handling, and safety.

How do you test a shock absorber?

There are several ways to test a shock absorber.

- Visual Inspection. Check for any signs of damage, such as leaks, cracks, or dents.

- Rebound and Compression Testing. This is the most accurate test to check a shock absorber. Basically, you put a shock absorber into a dyno machine that compresses and releases it and measures the resistance and damping force. LABA7 shock dynos were developed to do just that. During the test with our dyno machine, you can track the performance of the tested shock absorber in real time in several informative graphs. From these graphs you can quickly tell whether the shock absorber is worn or damaged, as the dyno notices when it operates inconsistently, is too soft or stiff.

- Bounce Test: This involves bouncing the vehicle at each corner and checking the suspension’s response. If the suspension continues to bounce excessively after the bounce, it is a sign that the shock absorbers need to be repaired or replaced.

- Road Test: A test driving of the vehicle can help identify any handling issues, noise or vibrations, and other signs that the shocks are not functioning properly.

It’s important to note that the specific testing methods may vary depending on the type of vehicle and the type of shock absorber being tested.

Is it OK to repair shock absorbers?

There can be three answers to this question and all would be correct. No, Maybe, and Yes.

No. If you are not a mechanic, we strongly do not recommend repairing shock absorbers yourself. They use precise components and even the slightest miscalculation can result in grave consequences. You might not only damage the shock but risk the safety of yourself and others.

Maybe. If it’s a cheap shock or fork sometimes it makes more financial sense to replace them, to be honest. In other cases, servicing would be a more viable option.

Yes. Generally, almost any shock or fork can be repaired. Especially expensive or racing shock absorbers, but this should be done by a trained and experienced professional with the necessary tools and expertise to do so safely and effectively.