MTB Shock Tester (Hand Shock Dyno) by LABA7

LABA7’s MTB Shock Tester, also known as the hand shock dyno, delivers precision suspension testing for mountain bike shocks, empowering mechanics with basic, data-driven insights into compression and rebound performance.

Two Models: Manual & Digital Mountain Bike Shock Dyno

Both Versions Include Mountings For:

- Trunnion Shocks – 55 mm, M10 x 1,5

- Strut Mount – M8

- FOX Brain – 81 mm

- FOX Brain 2.0 – 73 mm

- Eyelet Mounts (Top & Bottom): 8 / 10 / 12 / 12.7 / 15 mm

Digital Shock Tester Extras:

- Pancake-type load cell for high-precision force measurement

- Companion app (Android & iOS) for real-time force tracking

- Automatic max/min force lock, tare, calibration & report saving

- Powered by 3× AA batteries

Weight: ~15 kg

Dimensions WxDxH: 230 x 700 x 315

Manual MTB shock tester price: 950 EUR *

Digital MTB shock tester price: 1,300 EUR *

*(ex VAT)

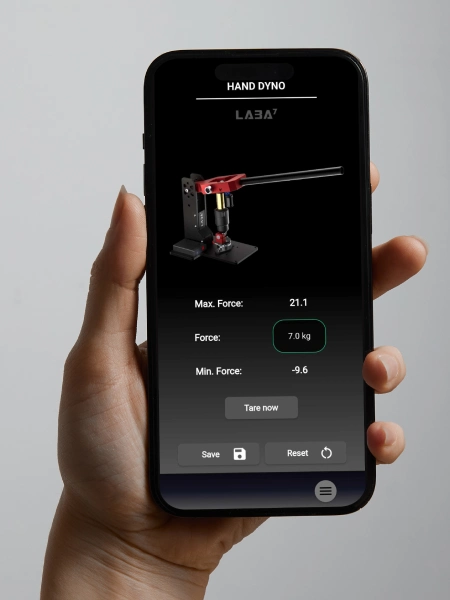

App Features for MTB Suspension Analysis

The sensor displayed in this image collects data on the force used to test a damper. This information is then transmitted to either an Android or iOS device for easy access and display.

This enables technicians to track how much force they use in each of their tests.

- Real-Time Force Display: Instantly view compression & rebound forces.

- Peak Force Lock: Auto‐capture maximum and minimum force values.

- Tare & Calibration: Zero the sensor and perform field calibration.

- Report Management: Save and export comprehensive test reports.

Why Choose LABA7 Hand Dyno?

Diagnose Problems Instantly

Quickly pinpoint leaks, gas loss, or worn parts for faster, more accurate suspension checks.

Verify Repairs

Confirm rebuild quality and service accuracy by testing the damper function in isolation.

Compare Setups

Benchmark fresh vs. used shocks or different models to optimize ride feel and component choice.

Detectable Suspension Issues Using Hand Shock Dyno

Using our hand shock tester, whether manual or digital, any technician with basic skills can analyze MTB dampers through a series of straightforward assessments.

Some examples of issues detectable with this shock absorber tester include, but are not limited to:

- Low-speed oil leaks in lock-out or high-threshold compression circuits

- IFP gas loss or under-charging of the internal floating piston

- Incorrect oil/gas mixtures inside the damper

- Misplaced IFP (verify correct piston positioning)

- Broken adjuster components (clickers, knobs, etc.)

- Loose piston bolts, pistons, or other internal parts

- Shim cracks or permanent deformations in shim stacks

- Oil fill level errors (too low or too high)

- Debris in the oil, causing intermittent damping failures

- Shuttling issues from slow or leaking check valves or loose glide rings

Frequently Asked Questions About MTB Shock Tester

What's the difference between the manual and digital MTB shock tester?

Both versions test the same shock types and mounting options. The digital version includes a precision load cell, smartphone app for real-time data, and automatic force tracking features, while the manual version provides basic compression/rebound testing without electronics.

Can the LABA7 shock tester work with all MTB shock brands?

Yes, it’s compatible with all major brands including FOX, RockShox, and others. It supports trunnion shocks, FOX Brain systems, and various eyelet sizes (8-15mm), making it universally compatible with modern MTB shocks.

What suspension problems can I detect with a hand dyno?

The tester can detect low-speed oil bleeding in lock-out or high-threshold compression circuits, identify IFP gas loss or undercharging, and evaluate gas mixture within the damper oil, plus broken adjusters, loose internal parts, and oil contamination issues.

Do I need technical experience to use the shock tester effectively?

Basic mechanical skills are sufficient. The tool allows technicians to conduct straightforward assessments, and the digital version’s app makes data interpretation easier with real-time force display and automatic peak force capture.

How accurate are the force measurements on the digital version?

The digital tester uses a pancake-type load cell for high-precision measurements, with automatic tare and calibration functions. The smartphone app provides real-time tracking and can save comprehensive test reports for comparison analysis.